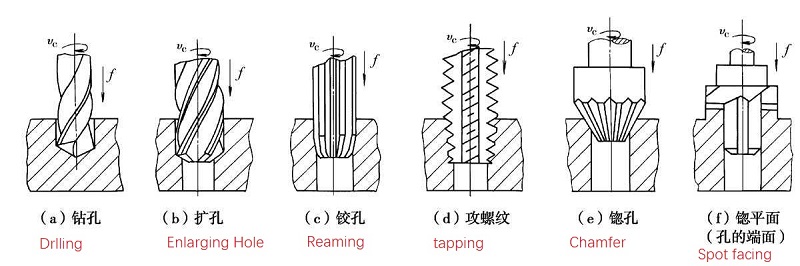

Hole processing method

Compared with the surface machining of the outer circle, the condition of hole machining is much worse, and it is more difficult to machine the hole than the outer circle. This is because:

1)The size of the tool used in hole machining is limited by the size of the hole to be machined, which has poor rigidity and is prone to bending deformation and vibration;

2)When the fixed size tool is used to process holes, the size accuracy of the holes often depends on the size of the tool directly, and the manufacturing error and wear of the tool will directly affect the machining accuracy of the holes;

3)When machining holes, the cutting area is inside the workpiece, the condition of chip removal and heat dissipation is poor, so the machining accuracy and surface quality are not easy to control.

1:Drilling and enlarging hole

1.1. Drilling

Drilling is the first process to machining holes on solid materials. The diameter of drilling is generally less than 80mm. There are two ways of drilling: one is the rotation of the drill; the other is the rotation of the workpiece. The errors produced by the two drilling methods are different. In the drilling method of bit rotation, when the bit is deflected due to the asymmetry of cutting edge or the lack of rigidity of the bit, the center line of the hole to be processed will deviate or not be straight, but the hole diameter is basically the same; However, when the workpiece is rotating and drilling, the situation is the opposite. The deviation of the bit will cause the change of the hole diameter, and the hole center line is still straight.

The commonly used drilling cutter include: twist drill, center drill, deep hole drill, etc., of which the most commonly used one is twist drill with a diameter specification of Φ 0.1-80mm.

Due to the structural limitations, the bending and torsional rigidity of the bit are low, and the centering is not good, so the drilling accuracy is low, generally only reaching it13-it11; The surface roughness is also large, RA is generally 50-12.5 μ m; however, the metal removal rate of drilling is large, and the cutting efficiency is high. Drilling is mainly used to process holes with low quality requirements, such as bolt holes, threaded bottom holes, oil holes, etc. For the holes with high machining accuracy and surface quality requirements, they should be achieved through reaming, reaming, boring or grinding in the subsequent processing.

1.2. Enlarging hole

Enlarging is to further process the drilled, cast or forged holes with the enlarge drill bit to enlarge the hole diameter and improve the processing quality of the holes. The enlarging hole can be used not only as the pre-processing before the finishing hole, but also as the final processing of the holes with low requirements. The enlarging drill bit is similar to the twist drill, but it has many teeth and no transverse edge.

Compared with drilling, enlarging hole has the following characteristics: (1) the number of reaming drill teeth is large (3-8 teeth), good guidance and stable cutting; (2) the enlarging drill has no cross edge and good cutting conditions;(3)Due to the machining allowance is small, so the chip holding groove can be made shallower, the drill core can be made coarser, so the strength and rigidity of the cutter body are better. The precision of reaming is generally it11-it10, and the surface roughness Ra is 12.5-6.3 μ M. Reaming is often used to process holes with a diameter less than 30. When drilling a hole with a larger diameter (D ≥ 30mm), a small drill bit (diameter is 0.5-0.7 times of the hole diameter) is often used to pre drill the hole, and then the corresponding size of the hole is used to drill the hole, so as to improve the processing quality and production efficiency of the hole.

In addition to machining cylindrical holes, reamers with various special shapes (also known as spot facers) can also be used to process various countersunk seat holes and spot facers. The front end of the spot facer is often provided with a guide column, which is guided by a processed hole.

2.Reaming

Reaming is one of the finishing methods of holes, which is widely used in production. For smaller holes, reaming is a more economical and practical processing method compared with internal grinding and fine boring.

2.1 Reamer

Reamers are generally divided into hand reamers and machine reamers. The handle of the hand reamer is straight, the working part is longer, and the guiding function is better. The hand reamer has two kinds of structures: integral type and adjustable outer diameter. The machine reamer has two kinds of structures: the one with handle and the one with sleeve. The reamer can not only process circular holes, but also taper reamer.

2.2 Reaming process and its application

Reaming allowance has a great influence on reaming quality. If the allowance is too large, the reamer has a large load, and the cutting edge is quickly blunt, it is not easy to obtain a smooth machining surface, and the dimensional tolerance is not easy to guarantee; The allowance is too small to remove the cutter mark left by the previous process, so it naturally has no effect on improving the hole processing quality. Generally, the allowance of coarse reaming is 0.35-0.15mm, and that of fine reaming is 01.5-0.05mm.

In order to avoid chip accretion, reaming is usually carried out at a lower cutting speed (V < 8m / min when machining steel and cast iron with a high-speed steel reamer). The value of the feed rate is related to the diameter of the processed hole. The larger the diameter is, the larger the value of the feed rate is. The feed rate is usually 0.3 ~ 1mm / R when the high-speed steel reamer processes steel and cast iron.

During reaming, proper cutting fluid must be used for cooling, lubrication and cleaning to prevent chip accretion and timely remove chips. Compared with grinding and boring, reaming has high productivity and easy to ensure the accuracy of the hole; however, reaming can not correct the position error of the hole axis, and the position accuracy of the hole should be guaranteed by the previous process. Reaming is not suitable for machining step holes and blind holes.

The size accuracy of reaming is generally IT9-IT7, and the surface roughness Ra is generally 3.2-0.8 μ M. For holes with medium size and high precision requirements (such as it7 precision holes), the drilling- enlarging- reaming process is a typical processing scheme commonly used in production.

3. Boring hole

Boring is a kind of machining method to enlarge the preformed hole by using cutting tools. The boring work can be carried out either on the boring machine or on the lathe.

3.1. Boring method

There are three different ways of boring.

(1)When the workpiece rotating cutter moves in feed, the boring on the lathe mostly belongs to this kind of boring method. The process features are: the axis of the hole after machining is consistent with the rotation axis of the workpiece, the roundness of the hole mainly depends on the rotation accuracy of the machine tool spindle, and the axial geometry error of the hole mainly depends on the position accuracy of the tool feed direction relative to the rotation axis of the workpiece. This kind of boring method is suitable for machining holes with coaxiality requirements with the outer circle surface.

(2) The tool rotates the workpiece for feeding movement, the spindle of boring machine drives the boring cutter to rotate, and the worktable drives the workpiece for feeding movement.

(3) The tool rotates and feeds; with this boring method, the overhanging length of the boring bar changes, and the stress deformation of the boring bar also changes. The hole diameter near the spindle box is large, and the hole diameter away from the spindle box is small, forming a taper hole. In addition, with the increase of the overhanging length of the boring bar, the bending deformation of the spindle caused by the self weight will also increase, and the axis of the hole to be processed will produce corresponding bending. This boring method is only suitable for machining short holes.

(to be continued)