1. Rubber Saddle- coil storage system and rollstop device:

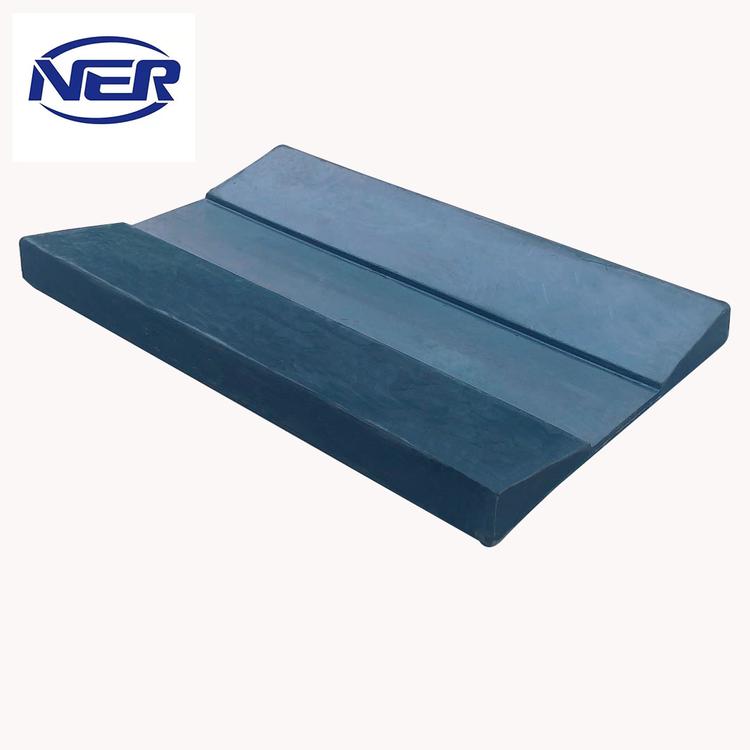

Die casting from rubber, rubber can be natural rubber or synthetic rubber with fabric reinforcement inside rubber.

Performance characteristics: It has the characteristics of pressure resistance, oil resistance, antiskid, wear resistance, corrosion resistance, etc. Flexible layout, not limited by the size of plant and warehouse. Suitable for steel coil, aluminum coil and other materials in coil. Loading capacity: 15-25 tons.

Main performance indexes:

(1) Shore hardness (A)90±5.

(2) ensile strength 12.6MPa.

(3) Elongation at break 240%.

(4) Application temperature -40~150°C

(5) Service life(Static state) 5 years.

(6) Good oil and corrosion resistance.

Standard dimensions:

L*W*H (refer to indication above picture)

600*600*85MM; 800*600*82(or 85)MM; 1000*600*82/85MM; 1200*600*85MM; 1500*600*85MM

Dimensions also can be customized if order quantity reach certain amount.

MOQ: 50 pcs

Many Chinese steel distributors use this kind of coil storage system.

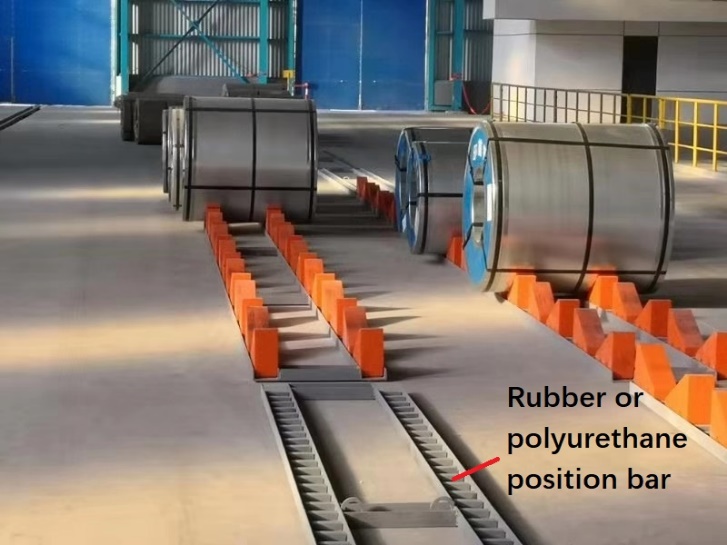

2. Steel Coil storage system- steel rail + steel saddle or polyurethane saddle.

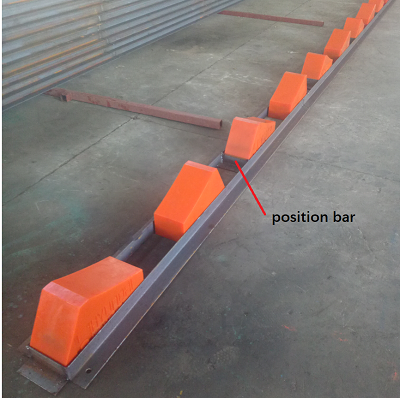

2.1-Steel rial + saddle; This steel coil storage system or rollstops device consist of two parts, one part is the steel rails, another part is saddle blocks (saddle blocks can be made from rubber or polyurethane or steel plus polyurethane).

The steel rails can be made of angle bars, or simply channel beams, refer to pictures above and below. The two rails are connected together by steel bar welded or bolted to form into a whole. The rails can be fixed on the ground by expansion bolts or just simply put on the ground.

Position bars or stops for preventing saddles moving are fixed on the rails, either on the certain location based on certain coil diameters, or evenly at a certain distance for saddles adjustment so that for different diameter coils.

We also can make rails more nicely, refer to the picture below. This one is fabricated of hot dip galvanized steel sheet by bending mostly with position holes on each side of rails. See below picture show how Steel Coil storage system look like.

We do not supply the steel rails normally, because it is very easy to be fabricated and does not make sense to be made from far away and transport from far away. If customers insist on, of course we can supply.

2.2. Polyurethane Saddle and steel plus Polyurethane pad saddle.

It can be made of polyurethane or rubber (mostly polyurethane, so here we only introduce polyurethane saddle). Polyurethane is better than rubber in many ways, so here we recommend polyurethane.

Polyurethane saddle for steel coil storage system;

Solid polyurethane blocks. Made from polyurethane completely.

Advantages and disadvantages:

- Good mechanical properties, high compressive strength, not easy to deform.

- Loading capacity of each saddle 10 tons;

- Good wear resistance performance.

- Very good corrosion resistance performance.

- Moderate hardness, good resilience, no damage to the coil.

- Easy to make.

- Disadvantages: a little expensive.

|

Hardness (Shore A) |

≥ 92 |

|

Tensile strength (MPA) |

≥ 40 |

|

Tear strength (KN / M) |

> 90 |

|

300% constant elongation (MPA) |

> 12 |

|

Akron abrasion (cm3 / 1.61km) |

≤ 0.03 |

|

Springback(%) |

> 25 |

|

Compression strength MPa (20%) |

35.6 |

Steel saddle + polyurethane pad.

See picture below, it is made of steel frame with polyurethane pad.

Advantages and disadvantages:

- Any loading capacity saddle can be made by using different steel thickness.

- Cheaper comparing polyurethane.

Disadvantages:

- Heavy.

We provide coil storage system solutions, either you need single rubber saddle rollstops or steel rail + polyurethane saddle coils storage system, we can supply with high quality and reasonable price, and quick delivery.