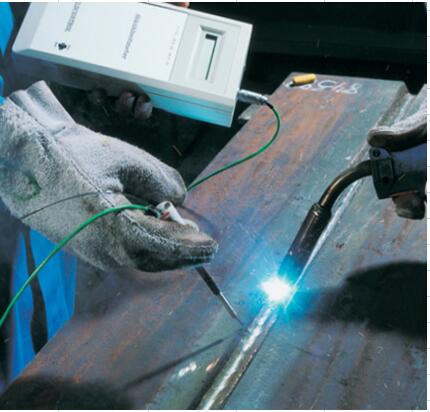

Big size welding structure, matters need attention for welding

1. Welding material must be dried according to instruction; welding rod shall be stocked in thermostat-container, take when you need.

2. Welding must follow welding procedures; no welding shall be carried out without reading welding procedures. Striking arc on the base material is not allowed for steel structure welding.

3. The welding electrode without cover or get rusted shall not be used any more. Also welding fluid become damp and agglomeration should not be used too.

4. Remove the oil and rust on welding wire before welding.

5. Welding wire and welding fluid must be dried for sufficient time according to instruction before use. The purity of protection gas must meet requirement of WPS. Low hydrogen electrode should be kept in thermostat-container taking when need for welding steel structure.

6. Check the size of welding bevel & root gap according to drawings and WPS etc. Technical documents, Sundries, harmful substances must be removed before welding when welding steel structure.

7. Submerge arc welding and Low hydrogen electrode for welding steel structure, the rust and oxide skin near welding seam area etc. other harmful substance for welding quality must be removed. Scavenging slag and spatter in positioning welding; the weld seam, slag and welding root must be removed on the back of the weld seam.

8. When crack happened while welding, welder cannot repair it by them, the reason of crack must be dig out and repair method and procedure should be draw up before repair it.

9. Repair welding on same welding seam should not be more than twice, when it must need, repair method and procedure should be draw up before repair it, when steel structure is fabricated.