一、Poor weld forming

1、Phenomenon

The welding waveform is poor, uneven and irregular, the transition zoon between welding seam and the base metal is not smooth, the welding joint is poor, and the height of welding seam is uneven.

2、Cause

analysis

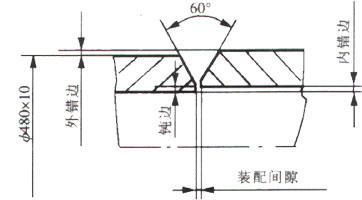

The reasons for the bad weld forming are in welding steel structure: the improper angle of the weld beveling or the uneven clearance of the assembly gap; the uncleanness of the welding joint grooves; the excessive or too small welding current; the excessive or too slow speed of the wire (gun) in the welding; the excessive or too small amplitude of the welding rod (gun); and the improper selection of the welding angle of the welding rod (gun).

3、Preventive

measures

(1)The groove angle and assembly clearance of the welded components must conform to the requirements of the design drawings or the performance standard.

(2)Welding groove must be cleaned, it must no rust, dirt, grease and other dirt impurities, revealing metallic luster.

(3) Strengthening the contact before welding, improve welder welding operation level, and be familiar with welding environment.

(4)According to the different welding position, welding method, different gap and so on, according to the requirements of welding process card and operation skills, the proper welding current parameters, welding speed and the angle of welding rod (gun) are selected in welding steel structure.

4、measures

(1) Strengthen self inspection and special inspection after welding,solving problems in time if found.

(2) Grinding and repairing the poor welding with

bad weld forming.

(3) Failing to meet the acceptance standard, and the

bad weld forming, it must be repaired by removing the welding and re-welding or

re-welding by replace a part.

(4) Strengthen the study of welding acceptance criteria and strictly follow the standard in welding the steel structure.

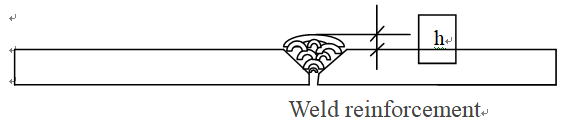

二、unqualified weld reinforcement

1、Phenomenon

The weld reinforcement of the pipe welding and butt weld of plate is more than 3mm; the local weld reinforcement is negative; weld reinforcement is too large; the height of fillet weld is not enough or is too large, and the excess height difference is too large in welding steel structure works.

|

Weld reinforcement

2、Cause

analysis

The selection of welding current is not proper; The moving speed

of the welding rod (gun) is not uniform, too fast or too slow; the amplitude of

the welding rod (gun) is not uniform; the welding angle of the welding rod is

improper.

3、Preventive

measures

(1) Reasonable welding current parameters are selected according to different welding positions and welding methods in welding components.

(2) Enhance welder's sense of responsibility, welding speed should be suitable for the selected welding current, and the speed of the moving wire (gun) is uniform, so as to avoid being quick and slow.

(3) The swing range of the welding rod (gun) is inconsistent, and the swing speed is reasonable and even.

(4) Keep the correct welding rod (gun) angle.

4、Measures

(1) Strengthen the training of welding operation skills and raise the level of weld cover.

(2) Carrying out the necessary grinding and repairing welding for welding.

(3) Strengthening the weld inspection after welding, and solve the problems in time if finding.

(4) In technical disclosure, the requirement of welding groove angle should be explained in detail.

三、Unqualified

welding width

1、Phenomenon

The weld edge is not straight, and the weld width difference is bigger

than 3mm in welding components.

2、Cause

analysis

Welding rod (gun) swing amplitude is not consistent, and at some

part is too large, at some part is too small; Welding rod (gun) angle is not

suitable; welding position is difficult, it impeding the sight of the welder in

fabrication and welding.

3、Preventive

measures

(1) Enhancing welder's responsibility, and improve

attention during welding.

(2) Take the correct welding electrode (gun) angle;

(3) Be familiar with welding position at site and

make necessary welding construction measures in advance.

4、Measures

(1) Strengthen practice, improve welder's operation level and improve the ability of overcoming difficult welding position.

(2) Improve quality awareness of welder and paying more attention to weld appearance quality when welding steel structure work.

(3) When the welding cover is finished, check in time, repair the unqualified weld, and repair welding if necessary.

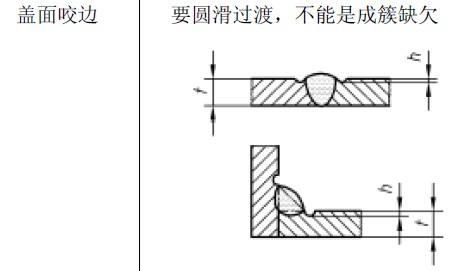

四、undercut

1、Phenomenon

The fusion between the weld and the base metal is not good, where

the groove is formed, the depth is greater than 0.5mm, and the total length of

undercut is larger than 10% of the weld length or larger than the length

required by the acceptance standard of steel structure.

|

2. Cause

analysis

The big weld heat input, the long welding arc, the incorrect welding

rod (gun) angle, and un-proper speed of the welding wire (wire) feeding, which

all can cause the undercut.

3、Measures

(1) According to the requirements of welding

project, location and welding specification, the suitable current parameters should

be selected.

(2) The length of the arc should be controlled and

the short arc welding is used as much as possible in welding steel components.

(3) Mastery of the necessary methods and techniques

for the moving of wires (guns);

(4) The welding speed of the electrode (or wire) is

coordinated with the selected welding current parameters.

(5) Pay attention to the angle of the welding rod

(gun) when the weld edge is melted with the base metal.

4、Measures

(1) Grinding, cleaning and repair welding of the

weld seam found in the inspection to meet the acceptance standard requirements

(2) Strengthening quality standard learning and

improving welder's quality awareness;

(3) Strengthen the practice and improve the

operation skills to prevent undercut defects.

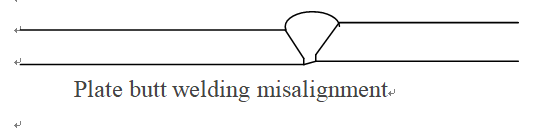

五、Welding Seam Misalignment

1、Phenomenon

It is shown that the base materials on the both side of the weld seam is not on the same plane, the misalignment is more than 10% of base material thickness, or it is bigger than 4mm.

Pipe misalignment

2、Cause analysis

Welding parts butt non compliance requirements, and welders do

the tack-weld and welding under inappropriate conditions.

3、Preventive

measures

(1) Strengthen the training for fitters on the

responsibility.

(2) The necessary measuring tools shall be used in

the butt joint.

(3) For weld-butt

failing to meet the requirements, welders shall not tack-weld or welding.

4、Measures

(1) Enhance standards and assembly skills

and improve the technical level of fitters.

(2) For welding joints with misalignment and failing

to meet the acceptance criteria, they should be removed, re-butt and re-welded

七 Arc crater

1 Phenomenon

In the ending arc, surface depression is formed, and it is often

accompanied by shrinkage cracks and other defects.

2、Cause

analysis

During welding, the welding pool is not full enough when stopping

the arc and welding, reasons is that welder cannot estimate the ending arc condition

so that the time of stopping arc is not proper.

3、Preventive

measures

(1) Prolonging the closing arc time.

(2) Take the correct method of closing the arc.

4、Measures

(1) Strengthen the skill training for welders, and

master various arc ending, arc stopping and joint welding operation methods in

welding steel structure works.

(2) Strengthen the welder's responsibility

(3) Cleaning and repairing the arc craters.

八、Weld

porosity

1.Phenomenon

During the welding process, the gas in the weld pool did not

completely overflow the weld pool (some of it overflowed), and the weld pool

has solidified, forming a hole in the weld surface.

2、Cause

analysis

(1) Gas is mixed into the molten pool during welding due to lax wind protection measures.

(2) The welding material is not cleaned or baked, and the welding

wire is not cleaned up, so the gas comes into the molten pool during welding.

(3) The temperature of the molten pool is low, and

the solidification time is short.

(4) The welding parts are not clean, and the

impurities generate gas to enter the molten pool when welding at high

temperature.

(5) When arc is too long, the protective gas flow

is too large or too small, and the protective effect is not good.

3、Preventive

measures

(1) The material and welding wire must be cleaned up

according to the requirements.

(2) The welding rod should be baked as required.

(3) Set up strict wind prevention measures, no

ventilation, etc

(4) Selecting proper welding line energy

parameters, the welding speed should not be too fast, the arc should not be too

long, and also mastering correct main points of start arc, moving wire and ending

arc.

(5) When argon arc welding, the protective airflow should be suitable and argon purity meets the requirements.

4、Measures

(1) Welding materials, the grinding and cleaning of

base materials shall be carried out in strict accordance with the regulations.

(2) Strengthen welder practice, improve operation

level and operation experience

(3) For the welding with surface porosity,

mechanical grinding should be used to remove defects, and repair welding if it

is necessary.

九、Surface slag

1、Phenomenon

In the welding process, slag formed between layers and layers caused by electrode covering (left), and it can be seen from outside.

2、Cause

analysis

(1) When the multi-layer welding, the coating slag between

layers is not cleaned and removed.

(2) The welding line has small energy and fast welding speed.

(3) Improper operation of welding

(4) The surface of the last layer welding is uneven

or the surface of the welded parts does not meet the requirements.

3、Preventive

measures

(1) Strengthen

the surface grinding of welding components, when it is multi-layer welding, coating

slag of electrode between welding layers must be cleaned before next layer

welding.

(2) Choosing reasonable welding current and welding

speed.

(3) Strengthen welders practice to improve the

level of welding operation

4、Measures

(1) Welding in strict accordance with the

requirements of procedures and work instructions of steel structure.

(2) For the welding with surface slag, the slag

must be grinded and removed, and repair welding if necessary.

十、Surface crack

1、Phenomenon

Surface cracks appeared in weld joints, fusion lines and heat

affected zones.

2、Cause analysis

The cause of surface cracks is different in steel types, welding methods, welding environment, preheating requirements, the content of impurities in welding joints, the assembly and welding stress etc., however, the fundamental causes for surface cracks are that there must be internal incentives and necessary stresses.

3、Preventive

measures

(1) Prepare various welding conditions in strict

accordance with the requirements of procedures and operation instructions.

(2) Improve welding operation skills and mastery of

welding methods.

(3) Reasonable welding sequence should be adopted

to reduce welding stress.

4、Measures

(1) Corresponding countermeasures should be taken

for each specific reason of cracking.

(2) For the welded joints with cracks, they should

be repaired by removing the weld and re-welding.

十一、The surface of the welding

components is not cleaned or not clean enough, and the arc damages the surface

of welding components.

1、Phenomenon

After welding, the coating of electrode, welding spatter are not removed or not cleaned, the coating of electrode and spatters left on the surface; In the process of welding steel structure, no attention is paid to the welding, so the arc damage the surface of welding components.

2、Cause

analysis

(1) The welder's responsibility is not strong and

the quality awareness is poor in doing welding steel structure.

(2) Welding equipment is not complete or defective

3、Preventive

measures

(1) Check the tools before welding, all the tools

and devices should be well prepared and functional.

(2) Strengthen technical disclosure, enhance

welders' sense of responsibility and improve quality awareness.

4、Measures

(1) Formulate preventive measures and strictly

implement it

(2) Increase the intensity of on-site supervision

and inspection, strictly check and accept the system, and find out problems in

a timely manner.

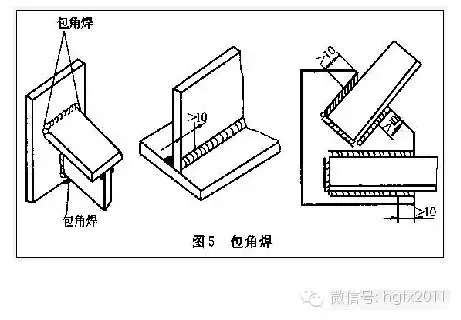

十二、No corner round welding for support

and hangers etc.T shape welding components

1、 Phenomenon

No corner round welding for T shape welding components

2、Cause

analysis

⑴ No technical basis by engineers or not make

clear

(2)Welders lack experience or have poor awareness of quality,

and they do not know enough about its hazards.

3、Measures

⑴ (1)The technical disclosure before welding is

carried out to clarify the welding quality.

⑵ Welders do welding strictly in accordance with

the quality standards.

4、Measures

⑴ Strengthen technical disclosure, improve quality

awareness of welders and recognize the hazards

⑵ Strengthen process supervision and inspection,

and solve the problems in time found.

十三、Welding

deformation

1、Phenomenon

Due to the different welding steel structure or welding components, the welding deformation is characterized by various forms, such as lifting, corner deformation, bending deformation, wave deformation and so on.

2、Cause analysis

The causes of welding deformation are: unreasonable assembly

sequence, strong counterpart, small welding shrinkage, unreasonable welding sequence

and so on

3、Preventive

measures

(1) Strict welding procedure should be made before

welding, and determine the assembly sequence, welding sequence, welding

direction, welding method, welding specification, welding line energy and so on.

(2) Technical disclosure shall be carried out before

welding, and welder works strictly according to the measures.

(3) The reverse deformation method can be used sometime

for welding components.

4、Measures

(1) Working in strict accordance with measures

(2) Welding technicians guide welding on the site.

(3) The necessary measures should be taken in time for

problems found finding out.