As the structural framework of steel structure, H steel beam supports the whole building structure system and bears and conveys all kinds of loads. Therefore, the quality of welding H steel beam directly affects the quality of steel structure, and highlights the importance of quality control of welded H section steel. The following we will introduce the quality control and process for welding H section according to the sequence of welding H steel beam fabrication.

The production process of welding H steel: steel plate cutting - flattening- assembly - welding – deformation correction - drilling holes- edge processing - sandblasting - coating - inspection- delivery

1. steel plate cutting and flattening

1.3 Steel plate cutting:Cutting methods for cutting materials include mechanical cutting, flame cutting and plasma cutting. In order to ensure the quality of steel plate cutting, it is required that the T3---T12 steel plate should be cut off by shearing machine, and the T12 plate should be cut by CNC flame cutting machine. There should be no cracks, slag inclusions, layer and truncation bigger than 1mm. The slag, oxide layer and tumor should be removed in time. And different parts should be stacked separately, and clearly marked, no mixing and not to be used indiscriminately.

Allowed deviation by Flame cutting

|

No. |

Description |

Allowed deviation |

T is thickness of steel plate |

|

1 |

Length & width |

±3.0 |

|

|

2 |

Flatness of cutting surface |

0.05t and ≤2.0 |

|

|

3 |

Depth of cutting lines |

0.3 |

|

|

4 |

Depth of local breach |

1.0 |

|

Item |

Description |

Allowed deviation |

|

1 |

The width & length of part |

±3.0 |

|

2 |

Truncation at cuttingsurface |

±1.0 |

|

3 |

Verticality |

±2.0 |

The allowable deviation between the cutting line and the draw line of the part 0.5mm,Before cutting, the rust and dirt near the cutting line on the steel plate should be removed and the slag and spatter on the edge should be removed after cutting. The finished cutting surface should meet the design standard. The size and quantity of pit defect per meter length during cutting: when the thickness of steel plate is less than 25mm, the allowable pit defect with size of height≤ 3 mm and length ≤1.5 mm no more than 2 per meter cutting line, if the size of pit defect bigger than the stated, it should be do welding correction , In general, thermal cutting should conform the standard of ISO 9013-2002.

1.2 Plate flattening: steel plate deformation is mainly warped, concave and convex unequal defects, H steel before the assembly and welding, the original material (steel plate) should be corrected and leveled.

Corrective methods: manual correction, heating correction or mechanical correction.

The following is the heating temperature for the flame correction (material is low carbon steel).

Low temperature correction 500 degree to 600 degrees, cooling : Water

Medium temperature correction 600 degree to 700 degree, cooling mode: Air and water.

Correction of 700 to 800 degrees cooling by high temperature: Air

Caution: when heating flattening, the heating temperature should not be too high, if the temperature is too high, it will cause steel embrittlement and affect the impact toughness of the material. Material 16Mn should not be cooled by water at high temperature in heating flattening, including thicker steel plate or hardened tendency.

Heat correction review: carefully check the quality of correction, if the first correction did not meet the requirements of the quality range, it should be flattened again by heating the place where first heated, if deformation of correction is too large, heating correction in the reverse direction once again to correct flame correction, until the technical requirements.

2. H profile assembly, welding and correction:

2.1 Assembly: Put steel plate (flange plate, web) into the H beam steel automatic assembly machine, in the assembly production line, Position the un-welded flange plate and web plate on the assembly machine by position devices, then do the positioning welding at head.

Welding the flange and web plate of H profile has the following requirements:

A. Flange plate: allowing splicing in length direction, not allowed in width direction, splicing length should not be smaller of 2 times the width of the plate, and the rolling direction should be parallel to the force direction.

B. The web can be spliced both in length and width direction, and the length of the splicing should not be less than 600mm, and the width of the splicing should not be small 300mm, allowing the "+" shape welding seam or “┷ ”,“┯”welding seams, but the gap between the two vertical joints should not be less than 200mm for “┷”and “┯”welding seams.

C. The distance between the flange splicing joint and the vertical splicing joint of the web should not be less than 200mm.

D. The spacing between the splicing joint of web plate and stiffening plate should not be less than 200mm.

E. The quality grade of the splice welding meets the design requirements.

2.2 H steel welding preparation: Section steel uses welding machine to welding, the welding of H steel beam production machine is generally submerged arc welding machine.

A. The corresponding welding method should be tested for the same welding joints with large number or representative joints in the project, after welding the self inspection should be carried on and the result should conform to the design requirements.

B. The welding materials and welding equipment and technical conditions shall conform to the standards of use.

2.3 Welding procedure

Pre weld inspection - loading arc board (according to requirements) - Welding - Inspection - fill out the operation record sheet.

Welding regulations

a. Before welding checking the beveling angle, root face, the gap and the wrong mouth all it should meet the requirements, and the rust, paint, oil and oxide skin in the slope and both sides should be cleaned up

b. The surface of the welding pad and arc plate is clean. It is required to be the same as the surface of the surface. The cushion plate and the parent material should be tightened and the arc plate and the base material should be soldering firmly (according to the requirements)

c. layer by layer to fill up the groove, After every one layer of welding, slag and spatter must be removed, if welding defects found , it should be removed and repaired in time.

d. A welding seam must be continuously welded and not stopped during the middle of welding.

e. Visual inspection is carried out after temperature of welding seam cooling to ambient temperature.

f. Welders and inspectors should carefully fill out the operation record sheet.

h. The general welding procedure: "first short, long later", "transverse first and longitudinal later" and “splicing welding first, fillet welding later".

i. It is strictly prohibited to strike arc or to debug the current on the base metal outside the weld area.

j. When the fillet weld between the rod and the gusset plate is welded by three sides or L girth welding, the corner of the weld must be continuously welded.

k. When the end of the fillet weld is on the bar, the corner should be welded continuously, and the start arc and end arc point should not be at the end, and it should not be lower by 10mm.

l、In any case, it is strictly forbidden to put the welding wire into the gap of the weld.

m, The welding surface pattern should be uniform, and there should be no defects such as cracks, slag inclusion, welding, and burning, non fusion and needle holes.

n、After examination, the welding seam which is unqualified quality should be repaired.

o. After the welding, the slag and the spatter on both sides of the weld should be cleaned in time, and the appearance quality of the weld should be checked, and the welding number of the welder should be put on the specified position after the welding.

2.4 H steel correction: The flange and web of welded H steel structure usually use thin steel plate, which can easily produce large welding deformation, and the verticality of flange plate and web is also deviant. This time it is necessary to correct the H steel after welding by the correction machine.

Process requirements: after completion of the correction, self inspection shall be conducted, and the allowable deviation is in conformity with the relevant provisions of the code for construction and acceptance of steel structures.

Allowed deviation after correction

|

Description |

Allowed deviation |

|

Local flatness of steel plate t≤14 t>14 |

1.5 1.0 |

|

Bending sagittal height1/1000 |

5.0 |

t: thickness of steel plate

3. Machining hole and edge machining: The connection nodes of steel structure mostly use high-strength bolts, so the holes processing takes a certain proportion in the manufacture of steel structures.

The method of machining hole: drilling and punching.

3.1 Attention to drilling:

a: When the steel plate needs to be spliced, drill holes must be carried after welding and flattening.

b: When drilling by the drilling machine, the parts should be leveled and clamped. If the workpiece is not drilled on the worktable, the drill should be kept perpendicular to the work. When the holes are in big diameter, small hole should be drilled for position, then enlarge the hole to required diameter.

c: When using a stacked hole, the edges of the parts should be aligned and the bottom holes quality should be ensure, and the quality of the drilling holes should be checked regularly. The quality inspector should regularly check the situation.

d: The surface roughness of the hole wall should not be more than 25 μm, and if the reuqirment is not high, then the allowable deviation is below:

Diameter: 0~+1.0mm,

Roundness: 2.0,

Verticality 0.03t and not bigger than 2.0。

e: Allowable distance deviation between holes (mm):

|

Range of hole distance |

≤500 |

≤501--1200 |

1200--3000 |

>3000 |

|

Any two holes distance in same group holes |

±1.0 |

±1.5 |

|

|

|

Distance between two adjacent groups of end holes |

±1.5 |

±2.0 |

±2.5 |

±3.0 |

3.2 Matters needing attention in punching press

a: The diameter of the punching hole should not be less than the thickness of the steel. The parts should be flat, stable, tight and fixed when punching, and the gap between the upper and lower dies of the punching is 10 ~ 15% of the thickness of the plate.

b: After loading the die, check the gap between the die whether it is uniform, and use the same material as the parts material to test, if the quality of test punching to meet the requirements after checking, then start the formal punching, it should be done by quality inspectors .

c: When punching in large quantities, the dimension of holes and the center distance between the two holes should be checked so that defects can be corrected in time in case defects found.

In a word, no matter the hole or the punching hole, there should be no cracks on the edge of the hole, and the flicker and the lack of 1.0mm greater than 1.5mm

3.3 The edge processing methods include: Edge shovel, planning, milling, carbon arc gouging, and gas cutting and beveling machining processing. The welded H column beam is corrected, the ends should cut flat, and the allowable error of end milling is shown in the following table:

|

Item |

Allowed deviation |

|

The length of component after milling both ends |

±2.0 |

|

The length of part after milling both ends |

±0.5 |

|

Flatness of milling |

0.3 |

3.4 Rust removal: steel structure surface treatment methods: rust removal by hand tool, steel wire wheel, acid cleaning and rust removal, sand blasting (ball) rust removal, and other organic solvents to remove the oil pollution and other dirt on the surface of the workpiece

4. Coating

Before painting, the time interval of painting should be determined. The places with special requirement for welding application and the around holes for bolts contact are prohibited to do painting. The paint damage area caused due to transportation, assembly, installation and installation have to be cleaned by cloth, using steel wire wheels grind the surface into certain roughness and at the same time to protect the assembly number, then sue pressure air clean the surface again, final finally paint the area second time according to the coating method. The total thickness of the paint film is required, the oil, dirt, dirt and other dirt on the surface of the component must be washed with water before second layer paint. A full-time QC inspector is responsible for checking, recording, numbering and stacking all processes, and there must be no missing or incorrect records

5. Finished product acceptance and shipment

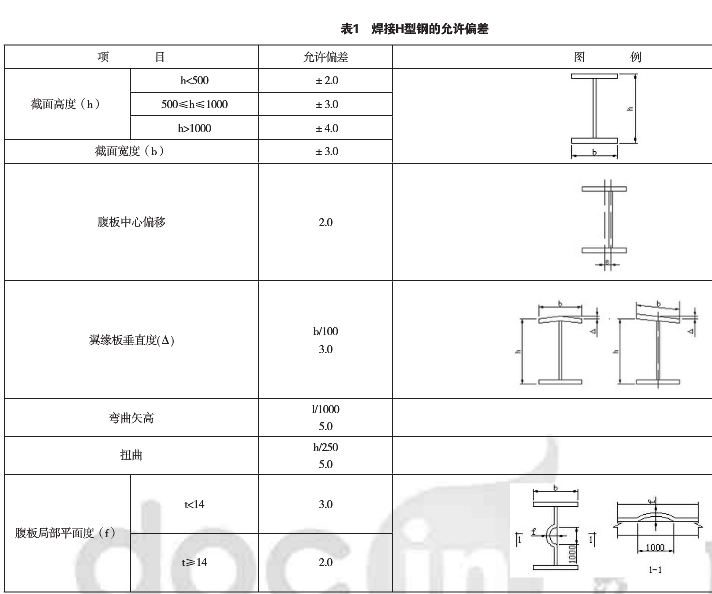

Finished products acceptance, numbering, packing and shipping: The welded H steel beams must be inspected and qualified, and then they can be shipped. The allowable deviation of welded H steel is shown in Table 1

A. according to the production and acceptance basis of steel structure, the finished products are checked and accepted.

B. Qualified after self inspection, fill in the self inspection and report to supervision engineer

C. The necessary documents for the acceptance of the finished products:

(1) Product certificate (2) construction drawings and design documents (3) Protocol documents for processing technical problems in the process of production (4) Certificate of quality of steel, connecting materials and coatings, or test reports. (5) Weld inspection record data (6) coating test data (7) main component acceptance record (8) component shipment list information below:

a. components are numbered before packing, converting various symbols into the number of components specified in the design surface, and marking the specified parts of the component with a pen (paint) or paste paper for the time of packaging.

b. should pay attention to the protection of components and coatings during transportation, and provide proper protection for vulnerable parts.

c. In case of deformation and damage, the repaired members should be repaired in time to ensure that the components are intact before shipment.

d. The loading of components should be packed well and secured, ensuring the integrity of components and preventing transportation losses.

6. Conclusion.

In the actual construction, the quality control of the welded H type steel can be achieved by controlling the qualified raw materials, selecting the reasonable processing technology and controlling the quality inspection of each process strictly, from the process of the whole welding H steel.