Precision welded-steel plate construction manufacturer

Guide reading

In this paper, taking a lifting platform underframe as an example, according to its structural characteristics and processing requirements, the welding method, welding sequence and manufacturing process are analyzed, and then the process plan is determined, which meets the functional design requirements, creates favorable conditions for the mass production of large-scale steel structural parts, and provides a reference for the manufacturing of other similar welded steel plate contracture parts.

Ship structural part is large-scale welded steel structural component, which ia the main stressed component of ship. The shape and peripheral contour of parts have assembly relationship with other components and parts, they not only meet the requirements of assembly coordination with other parts, but also meet the requirements of their own structural dimension accuracy and quality. With the development of ship structural parts to large size, the result is that the structure of parts becomes more complex and a large number of high-precision assembly holes appear. As the size of the parts increases, the machining accuracy of the parts is not reduced but required to be higher, which greatly increases the manufacturing difficulty.

1.Part structure Characteristic

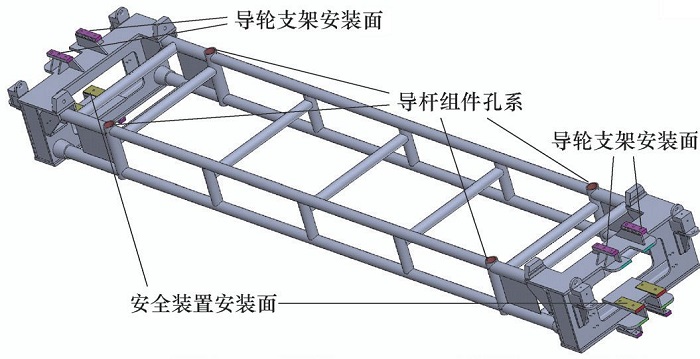

Taking the underframe of a lifting platform as an example, the maximum dimension of the part is 6196mm × 1180mm × 715mm, which is welded by 32 kinds of parts (Grade 20 steel pipes, Grade Q235B channel steel and Grade Q345B steel plate), belonging to a large welded steel structure parts (see Figure 1),

Figure 1 Lifting platform underframe model

2.Process emphasis

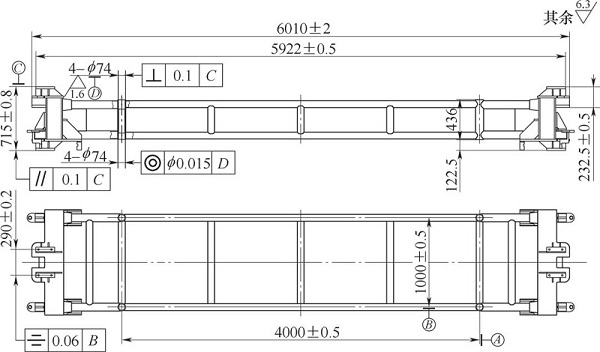

The main dimensions of the base frame of the lifting platform are shown in Figure 2. The coaxiality of the hole system of the guide rod assembly is φ 0.015m m, the perpendicularity of the connection surface with the guide wheel support is 0.1mm, the surface roughness value is ra = 1.6 μ m, the parallelism of the connection surface of the guide wheel support is 0.1mm, the symmetry of the four groups of installation holes is 0.06mm, and the accuracy is very high.

Figure 2 Main dimensions of lifting platform

In consideration of the structural features and overall dimensions of the lifting platform, the process focuses are as follows:

(1).Due to the large size, complex structure, many parts, difficult to control the size and large welding deformation of the part, the welding deformation shall be controlled during welding and the accuracy of the welding position of the four guide steel pipes, the mounting surface of the guide wheel bracket and the mounting surface of the two safety devices shall be ensured.

(2).Ensure the coaxiality and position of the hole system of the four groups of guide rod assembly, as well as the verticality of the connection surface with the guide wheel support; also ensure the parallelism of the upper and lower connection surfaces at both ends, and the symmetry of the upper and lower connection surfaces at both ends and the four groups of holes.

(3).Processing method of the mounting surface and hole of the safety device.

3. According to the structural characteristics and accuracy requirements of the lifting platform underframe, the welding and processing are analyzed as follows.

(1).Welding. Due to the large size of the part, the position accuracy of the four guide steel pipes, the mounting surface of the guide wheel bracket and the mounting surface of the two safety devices is very high after welding, so there should be a welding platform large enough and suitable for the fabrication of the large steel structure part. When making the tooling, fix four guide steel pipes first, take the end faces of the four guide steel pipes as the reference plane, and assemble the platform frame with the actual position and size of the steel pipes on the welding platform. From the outside to the inside, place the parts in sequence first long and then short, and pre compress them. Keep the distance between the pressing plate and the welding position so that the welding is not affected. The steel pipe connection is fixed by a special clamp, and then the steel pipe is fixed by spot welding. Intermittent welding, symmetrical welding and flat welding are adopted to complete the welding of platform body frame. After all the horizontal welds on the upper plane are welded, release the pressing plate and clamp, turn the workpiece 180 ° and then press and lock the workpiece to complete the welding on the other side of the workpiece.

Each assembly and welding process shall be locked and fixed with tooling clamps, which shall be removed after the workpiece cools naturally. n case of welding deformation, it shall be corrected and leveled in time. It is strictly prohibited to use hammer during correction. Rubber hammer or wood hammer shall be used, and rubber base plate shall be applied at the stress point during mechanical correction. After the workpiece is straightened after welding, the welding and correction of the steel pipe connection of the frame body are completed in turn. After the underframe body is welded, the positioning and pressing tooling shall not be disassembled immediately, and can only be disassembled after the stress relief process is completed, and the welding stress shall be fully eliminated during the welding process.

According to the structural characteristics and parts distribution of the parts, the welding sequence of the lifting platform underframe is: steel pipe assembly, welding and rectification (steel pipe frame body) → frame base at both ends → square steel and stiffener → connecting surface of the upper guide wheel bracket → connecting surface of the safety device → connecting surface of the lower guide wheel bracket.

(2).Processing. As the part is a large-scale welding structure, the stability of accuracy is poor, and the welding deformation is large, so the stress generated during welding needs to be fully eliminated. For this reason, two artificial aging treatments are arranged in the manufacturing process, which are respectively arranged after welding and rough machining, to fully eliminate machining stress and ensure the accuracy of hole and datum plane through rough machining and semi finish machining.

Roughing and semi finishing are arranged on HGMC 30100 gantry machining center, and finishing holes are arranged on 12m Okuma pentahedral gantry machining center with high precision, Because the four groups of hole systems and connecting surfaces of the part are on four different surfaces, and the requirements of form and position tolerance are high, it is necessary to unify the process datum, process the process datum under the condition of stable state of the part, and then finish the finishing, and unify the process datum to ensure the requirements of form and position tolerance. The parts shall be placed side by side, clamped once, and the horizontal milling head shall be used to rotate the machining hole and datum plane, so as to reduce the error caused by the secondary clamping. Pay attention to the inspection rod to check the axis of the milling head when the horizontal milling head rotates, and eliminate the machine error. The mounting surface of the safety device of the part and its hole are in the inner cavity surrounded by each plate, the inner cavity size is small, and the horizontal milling head is not suitable for direct processing. In view of this situation, the horizontal milling head is used to install the small right angle milling head to complete the processing of the inner cavity surface and hole of the end face. The final processing flow of the lifting platform underframe is: welding → stress relief treatment (artificial aging) → rough processing → benchwork → stress relief treatment (vibration aging) → semi finishing → finishing → benchwork → paint.

4.conclusion

Large steel structural parts are the main stressed parts of ships, which play an important role in the manufacture of large ships. Their processing quality is directly related to the assembly coordination relationship and service life of ships. Through the research of the lifting platform process plan, from the welding method, welding sequence to the processing process, through the processing verification, it meets the requirements of the functional design, creates favorable conditions for the mass production of large-scale structural parts, and also provides a reference for the manufacturing of other such parts.