Large steel frame fabrication and machining is a common product in large-scale machining at present. In addition to the processing requirements of steel frame fabrication and welding, we should also know the technical requirements of machining. What are the technical requirements of large steel frame fabrication and welding?

1. The welding position of the steel frame shall avoid the stress concentration area and be convenient for welding.

2. The welding preparation and beveling of steel structure fabrication shall be processed according to the drawing. When there is no clear specification on the drawing, the welding preparation and beveling size shall be selected according to these principles: To ensure the welding quality; to minimize the amount of filler metal for welding, to facilitate the operation of welders, to reduce the welding stress and deformation, etc.

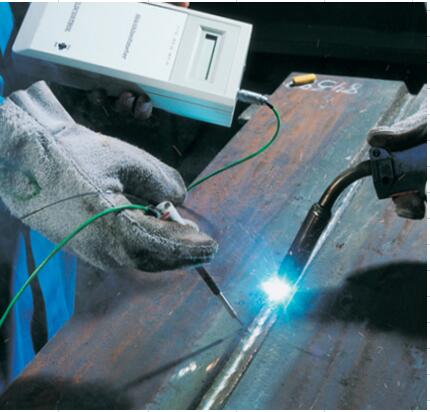

3. Before assembling all parts of the steel frame, the oil, paint, scale, rust, burr and galvanized layer on and near the welding surface shall be removed and expose the metallic luster.

4. When the welding gap of the steel frame is too large, it shall be repaired to make the welding gap reach the specified size range. It is strictly prohibited to insert filler in the gap.

5. The welding rod, welding wire and flux used for welding large steel frame and steel fabrication shall be stored in a dry place with good ventilation, temperature greater than 5 ℃, and relative air humidity less than 60%. The welding rod and wire for welding important parts shall be stored in a special heat preservation cylinder with a temperature of 100-150 ℃, and shall be taken as needed.

6. When assembling all parts of the steel frame, the workpiece shall be fixed firmly to prevent deformation and additional stress due to uneven temperature during welding.

7. Except for the parts which are allowed to use cold external force to position the welding seams specified in the design drawings, the rest are forbidden to use strong external force to assemble and position the weld joint, and it is not allowed to use the heating expansion method to position the weld joint to prevent additional stress in steel fabrication.

8. In order to ensure the quality of welding seam in steel fabrication, the welding site shall be windproof, rainproof, snow-proof, cold proof, etc.

9. For the welding seams requiring preheating and post welding heat treatment, the pre heating and post heating tooling, temperature measuring instruments and thermal insulation protection articles shall be prepared before welding.

10. When downhand welding in steel fabrication, ensure that the longitudinal weld and transverse weld (especially transverse) can contract freely. When welding butt weld, the welding direction shall point to the free end.

11. When welding the steel frame, the weld seams with large shrinkage shall be welded first. If there are butt welds and fillet welds on the steel structure, the butt weld with large shrinkage shall be welded first.

12. When welding steel frame, the short transverse weld shall be welded first.

13. During the fabrication and welding of the steel frame, the weld seams with large stress shall be welded first to make the internal stress distribution reasonable.

14. For the steel structure with large welding deformation, the welding stiffener can be used properly according to the actual situation.

15. The steel structural parts composed of multiple members shall be assembled and welded step by step, and the general assembly welding shall be carried out after the deformation is corrected.

16. After the completion of the welding and fabrication

of the steel frame, the whole internal and external surface or part of the

surface of the steel frame shall be corrected and cleaned.

After welding and fabrication, the surface of the steel frame should be cleaned

by shot peening, which can better improve the fatigue strength of the frame.

The above 17 are the technical requirements of large-scale steel frame fabrication. The welding workers should pay attention to these technical requirements when welding and fabrication large-scale steel frame, so as to better improve the quality of steel frame in steel fabrication.