The demand for elevator sheet metal parts in China will reach 870000 tons in the future

Elevator parts include mechanical parts, sheet metal parts, electrical parts and standard parts, of which 60% are sheet metal parts, involving nearly 1000 kinds. According to raw materials, elevator sheet metal parts can be divided into three categories: stainless steel, galvanized steel, carbon structural steel.

According to the plate thickness of raw materials, it can be divided into thin plate (0.2-0.8mm), medium plate (1-1.5mm), medium thick plate (2-3mm) and thick plate (4.5-6mm)。According to the use, elevator sheet metal parts can be divided into load-bearing type, decoration type, decoration and load-bearing composite type and safety protection type。

Classification of elevator sheet metal parts

|

Classification basis |

category |

|

Classification basis |

Stainless steel sheet, Galvanized steel sheet, Carbon steel plate |

|

Sheet thickness |

Thin steel sheet (0.2-0.8mm); middle thick. Steel sheet(1-3mm); thick. Steel plate (4.5-8mm) |

|

function |

Load-bearing class; Decoration class; decoration and load-bearing composite type and safety protection type. |

2、Elevator sheet metal process: cutting, stamping, bending and connecting

The main raw materials for elevator manufacturing are all kinds of steel plates, including steel plate, angle steel, channel steel, stainless steel plate, cold drawn section steel, etc. the main process is general sheet metal processing, including cutting, stamping, bending and connection as the main forming process.

Process analysis of elevator sheet metal parts

|

Technology |

Content |

|

Shear |

universal shearing machine |

|

Stamping |

Press stamping: Applicable to Shim, Parts in hoist-way, stiffener and cover cap |

|

NC punching: |

|

|

Bending |

The bending machine for elevator sheet metal parts is mainly 2-3m long, and the pressure is between 130-250t |

|

Connection |

The connection methods of sheet metal parts on elevator mainly include welding (gas shielded welding and resistance welding), bolt connection, riveting and bonding. |

3、China's elevator production increases year by year, but the growth slows down

After the rapid development of China's elevator industry, at present, the domestic elevator industry has entered a stable development period, with little change in annual new output, but the growth rate has begun to decline. In the next 3-5 years, the new elevator market mainly depends on the demand of housing construction, shantytown transformation, urban rail transit, public infrastructure construction, etc. in addition, there is an important demand for the old building to install elevators. In the report on the work of the government at the second session of the 13th National People's Congress in 2019, it was clearly pointed out that "there are a large number of old urban communities, which need to be vigorously upgraded, updated water, electricity, gas and other supporting facilities, supported the installation of elevators and the construction of barrier free environment, and improved the convenience market, convenience stores, pedestrian streets, parking lots and other living service facilities."

In 2018, 850000 elevators (including escalators and moving sidewalks) have been produced in the whole industry, an increase of 5.33% compared with 2017, of which about 760000 for domestic market and 90000 for export.

Statistics and growth of elevator production in China from 2013 to 2018

(Note: the growth rate of production in 2014 was 14.46%)

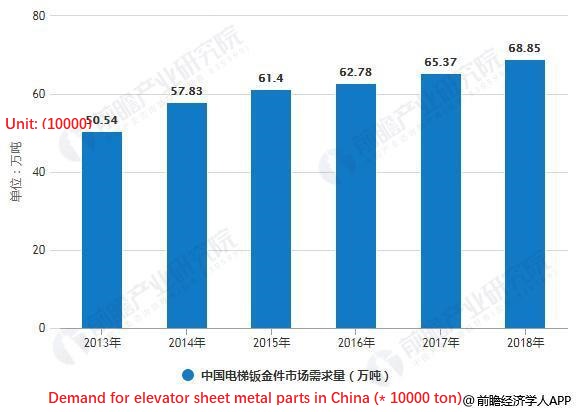

4、The consumption of elevator sheet metal parts increases year by year

At present, the development trend of elevator sheet metal industry in China is relatively good. Along with the investment promotion in the past decade, it has laid the foundation environment for the improvement of the manufacturing level of elevator sheet metal parts, and the production capacity has been gradually improved. According to statistics, if an average elevator needs 810kg of steel, the demand for elevator sheet metal parts in China will be 688500 tons (850000 * 0.81 tons) in 2018, and so on in other years.

The huge market and central position will further attract the transfer of manufacturing center of multinational sheet metal companies to China.

2013-2018 China elevator sheet metal market demand statistics

Economic development, urbanization process, installation and renewal of old building elevators and export market are the four driving factors for the future development of China's elevator industry. China will still be the largest elevator market in the world for a long time in the future. In addition, because the elevator industry needs more sheet metal structure parts, some leading enterprises outsource sheet metal processing business, so it seems that the market potential of sheet metal outsourcing business in China's elevator industry in the future is huge. It is estimated that the demand for elevator sheet metal parts in China will reach 870000 tons by 2024.

Market demand forecast of elevator sheet metal parts in China in 2019-2024

The above data sources refer to the market demand forecast, transformation and upgrading analysis report of China's sheet metal processing industry issued by the prospective industry research institute. Meanwhile, the prospective industry research institute also provides solutions such as industrial big data, industrial planning, industrial declaration, industrial park planning, industrial investment promotion, etc.

China is becoming more and more an international processing and manufacturing center. With the increasing foreign investment, the demand for metal precision processing capacity is increasing. In the metal processing industry, electrical control boxes, machine casings, etc. are generally sheet metal parts, so the demand for sheet metal processing capacity is also increasing. The export growth rate of the main sheet metal products is higher than that of the output, and higher than that of the domestic market sales. The main sheet metal products are in full bloom, not only the traditional export products such as electric tools, hand tools and construction hardware products have a high growth rate, but also the export growth rate of the kitchen and electric products and bathroom products with a small proportion of the previous exports in 2004 is very obvious. The huge market and central position will further attract the transfer of manufacturing center of multinational sheet metal companies to China.