Flame correction method of steel structure after welding deformation

Abstract:Flame correction is a common method to solve the welding deformation in the manufacturing process of steel structure. This paper mainly introduces the method and process of flame correction after the welding deformation of steel structure.

Key words: steel structure, welding deformation, correction

1. Preface

At present, steel structure workshop is widely used in China. The main components of the steel structure workshop are welded H-shaped steel columns, beams and supports. These components have welding deformation problems in the manufacturing process. If the welding deformation is not corrected, it will not only affect the overall installation of the structure, but also reduce the safety and reliability of the project. When the deformation of welded steel structure exceeds the allowable deformation range of technical design, it shall be corrected to meet the product quality requirements.

There are three correction methods widely used in the production process: mechanical correction, flame correction and comprehensive correction. But flame correction is a difficult work, If the operation process and temperature are not properly controlled, the new and larger deformation of the component will be caused. In the past 40 years, China has built a large number of steel structure facilities such as factory buildings, bridges, highways, airports, high-speed railway stations, so Chinese steel structure manufacturers have accumulated rich experience in manufacturing and deformation correction.

2. Principle of gas flame correction

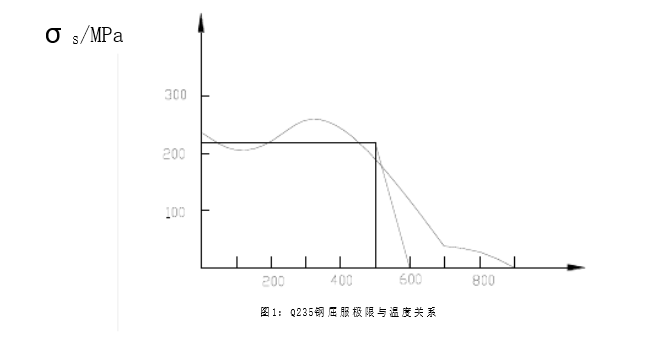

Metal has the characteristics of heat expansion and cold contraction, and its mechanical properties also change with the change of temperature. The relationship between yield limit σ and temperature of low carbon steel (take Q235B steel as an example) is shown in the dotted line in Figure 1. In general, it can be simplified as a solid line, that is, when the temperature is below 500 ° C, the yield limit basically does not change; when the temperature is higher than 600 ° C, the yield limit is close to zero. The temperature varies linearly between 500-600 ° C.

When the metal structure is locally heated, the thermal expansion of the metal in the heating area is prevented by the surrounding cold metal, and the metal in some parts cannot be deformed freely, and the metal in some parts is plastic compressed. After cooling, the residual local shrinkage makes the structure obtain the required deformation.

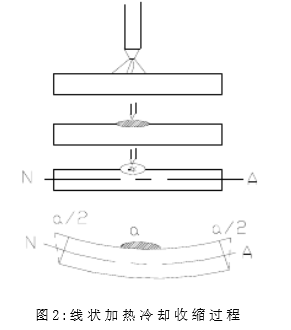

2.1 Linear heating

The principle of the linear heating method is shown in Figure 2. After the steel plate surface is heated, the surface temperature closest to the hot spot rises the fastest and expands the fastest, and the area around the heating point is less affected by heat and expands very little. After the heating stops, the temperature diffuses to the surrounding, the heated part begins to cool, and the shape gradually recovers. However, due to the contact between the steel plate surface and the air, the heat dispersion is faster, so the heated part of the steel plate surface has been fixed before it recovers.

As the cooling process continues (Figure 2), The high temperature on the upper side of the central axis begins to contract, and its contraction force causes the plate to bend upward. After the bending is terminated, both ends of the steel plate are shortened by a / 2, but the middle part is raised by A. The flame moves along the straight direction of the steel plate, and in order to widen the heating line, it can also swing laterally to form a long strip heating.

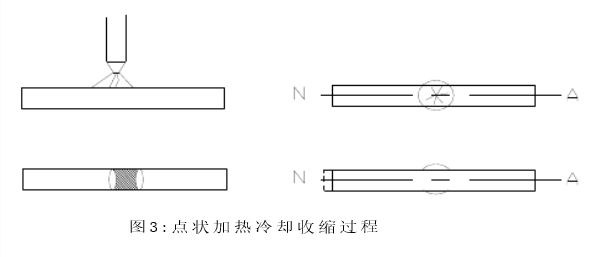

2.2 Point heating

When heating the sheet, because the sheet is thin, the surface heat is transferred to the inside quickly, and the high temperature part goes through the cross section of the whole sheet. When cooling, the cooling temperature of the upper and lower surfaces is the same, and the cooling shrinkage force of the upper and lower sides of the central axis is the same, so the expansion part of the upper and lower surfaces is retained during heating, resulting in the overall shortening of the plate, but no bending. As shown in Figure 3

The position of hot spot is relatively fixed during shortening processing. This method is generally used for wave deformation of thin plates.

2.3 Heating temperature

The central flame or oxidation flame with a mixture ratio of 1:1.05-1:1.25 is suitable for flame correction. According to the heating temperature of flame correction, it can be divided into three types: low temperature correction, medium temperature correction and high temperature correction. The corresponding heating temperature and cooling medium are shown in Table 1.

Form 1

|

Classification |

Heating temperature℃ |

Low carbon steel heating color |

Cooling medium |

|

Low temperature correction |

500-600 |

Red dot in the light |

water |

|

Medium temperature correction |

600-700 |

Dull red |

Air and water |

|

High temperature correction |

700-800 |

Light Peach Pink |

air |

2.3.1 Low temperature correction for low carbon steel

According to Fig. 1, when the temperature is 500-600 ℃, the yield limit of low carbon steel has been greatly reduced. Heating to this temperature range can achieve the purpose of flame correction, and the metallographic structure and mechanical properties remain unchanged. The cooling rate can be increased by spraying water properly, so as to improve the efficiency of flame correction. Low temperature correction is seldom used in actual production.

2.3.2 Medium temperature correction

The heating temperature of the metal is 600-700 ℃, and the yield limit σ is close to zero. When the heating temperature is still below the phase transformation temperature, the metal structure has no phase transformation, so the mechanical properties of the metal have little change. Medium temperature correction is often used in our actual production.

2.3.3 High temperature correction

Although there is phase transformation of metal structure in this temperature range, annealing structure can still be obtained after Q235B, q235f and Q345B steels are cooled in air, and other mechanical properties have little change. However, if the heating temperature is too high, austenite grains will grow up, and they will not be refined in the cooling process, which will increase the brittleness of the metal and reduce the impact toughness.

It should be noted that water cooling is not allowed when Q345B steel is heated to transformation temperature, otherwise low carbon martensite will be produced and impact toughness will be affected.

For the heating temperature, it should also be noted that the linear heating should be limited to 650 ℃, and the point heating should be limited to 750 ℃.

3. Flame correction method for different welding deformation

Due to the limited size and specification of hot-rolled section steel produced by China steel mills, mainly various H-section steel, which cannot meet the design requirements for heavy steel structure, especially the heavy H-section steel and beam required, therefor

many large-scale columns and beams are fabricated in the steel structure workshop.

The main structural members in the steel structure are welded H-shaped steel beams and columns. Three kinds of flame correction methods are often used for welding deformation: (1) linear heating method; (2) point heating method; (3) triangle heating method. The following describes the correction methods for welding deformation of different parts in China's steel structure manufacturers.

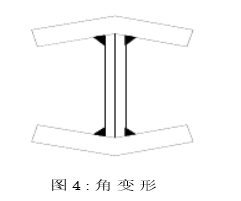

3.1 Angular deformation of flange plate.

Correct the welding angular deformation of H-beam and column. On the flange plate (on the opposite side of the weld), longitudinal linear heating shall be carried out along the weld, and it shall be noted that the heating range shall not exceed the range controlled by two welds, and water cooling can be avoided, as shown in Fig. 4. During linear heating, attention shall be paid to:

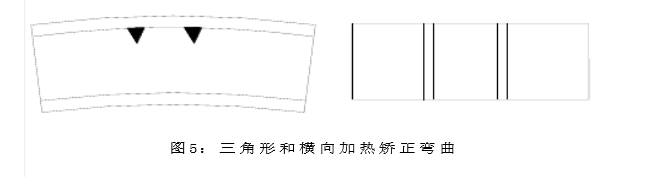

3.2 Up arch (down deflection) bending of beams and columns

Method 1: On the upper side of the flange plate, the bending deformation can be corrected by linear heating from the middle to both ends along the longitudinal long weld seam. In order to avoid side bending and distortion, the two heating belts should be carried out simultaneously, and low temperature correction or medium temperature correction can be adopted. This method is beneficial to reduce the internal stress of welding, but it is difficult to master because of its large transverse shrinkage at the same time of longitudinal shrinkage.

Method 2: make linear heating on the flange plate and triangular heating on the web, as shown in figure 5. Correct the bending deformation of beams and columns with this method, and the effect is obvious. The width of transverse linear heating is usually 20-90mm. When the thickness of the plate is thin, the heating band should be narrower. The heating process should be extended from the middle of the width to both sides. Linear heating is better done by two people at the same time, and then heating triangles separately. The width of the triangle shall not exceed 2 times of the plate thickness, and the low width of the triangle shall be equal to the linear heating width of the corresponding flange plate. The heating should start at the top of the triangle, then extend from the center to both sides, heating layer by layer until the bottom of the triangle. When the web is heated, the temperature should not be too high, otherwise it is easy to cause concave deformation and difficult to repair.

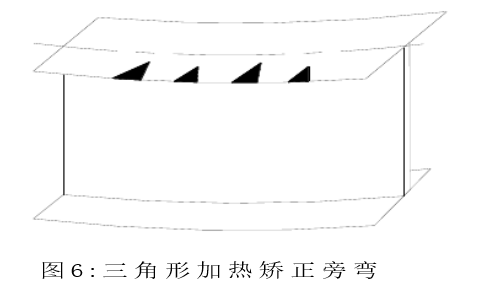

3.3 Side bending deformation of beams and columns

For the side bending deformation of beams and columns, triangle heating is applied to the edge of wing plate, as shown in Figure 6

The specific methods and requirements are as described in 3.2. Use medium temperature correction, less water spray, like shower degree. In addition, it should be noted that water cooling is not allowed for steel with large plate thickness or hardening tendency. In order to improve the rectification effect and quality, the flange plate is strengthened to the concave side with a clamp during the heating process.

4 Concluding remarks

The stress caused by flame correction is the same as the welding stress. The internal stress produced by improper correction will be superposed with the welding internal stress and load stress, which will make the longitudinal stress of columns, beams and braces exceed the allowable stress, thus leading to the reduction of the bearing safety factor. Therefore, when deformation correction is needed in steel structure fabrication, it is necessary to be cautious. Reasonable process measures shall be adopted to reduce deformation as far as possible, and mechanical correction method shall be adopted as far as possible. When flame correction has to be adopted, the following points shall be paid attention to:

(1) The heating position shall not be near the maximum stress section of the main beam;

(2) The heating area shall not be too large at one section, and more sections shall be selected;

(3) It is better to use point heating to improve the stress state of heating zone;

(4)The heating temperature should not exceed 700 ℃.

The above experience is shared by a Chinese steel structure manufacturer. There are many excellent steel structure manufacturing enterprises in China, and they have accumulated rich practical experience in China's large-scale construction in the past decades