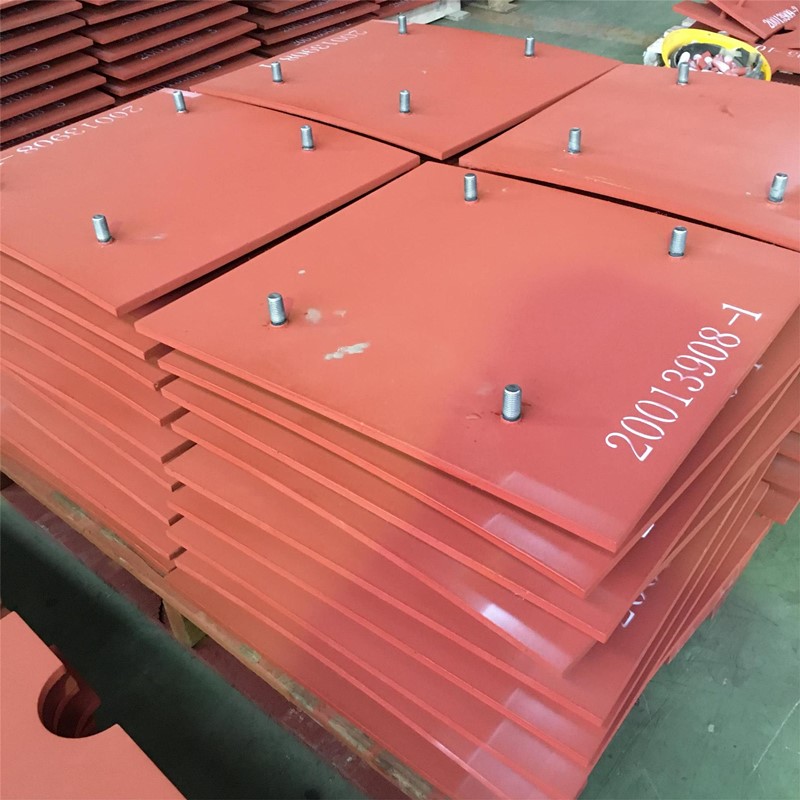

The wear-resistant steel lining plate for vertical mills processed for Chilean customers has been finished, totaling 120 tons. At the end of the month, it is ready to pack and ship.

This liner is made of ThyssenKrupp wear-resistant steel plate, XAR 450, thickness 12. Processing technology includes cutting, rolling, dividing into small pieces (size of parts), welding bolts (stud welding), painting and so on.

If we consider the cost, we can also choose China wear-resistant steel NM450 to fabrication. The price is only half that of imported wear-resistant steel plate (e.g. Hardox 450, XAR 450, DILLIDUR 450V).

The technical parameters of XAR 450 are as follows:

|

Wear-resistant special structural steel

Heavy Plate

|

Steel grade |

Material No |

Material Specification 710 October 2012 |

|

|

TKSE-Short name |

EN-Short name |

|||

|

XAR® 450 |

- |

1.8722 |

||

Scope

This Material Specification applies to 3 to 100 mm (0.118 to 3.937 in.) thick plates of the wear-resistant special structural steel XAR® 450.

Application

The steel may be used at the discretion of the purchaser for wear-exposed structures, e.g. excavating, mining and earth-moving machinery, truck dump bodies, conveying, crushing and pulverizing equipment, scrap presses, paving moulds and in switch manufacturing.

The processing and application techniques as a whole are of fundamental importance for the successful use of the products fabricated of this steel. The processor/fabricator must assure himself, that his design and work methods are appropriate for the material, are state-of-the-art and are suitable for the envisaged purpose.

The selection of the material is left up to the purchaser.

Chemical composition (heat analysis, mass.%)

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

B |

|

≤ 0.22 |

≤ 0.80 |

≤ 1.50 |

≤ 0.025 |

≤ 0.010 |

≤ 1.30 |

≤ 0.50 |

≤ 0.005 |

The steel has a fine-grained microstructure. Nitrogen is absorbed to form nitrides by means of Al and, where applicable, Nb or Ti.

Delivery condition: quenched or quenched and tempered (see paragraph “Heat treatment”)

Hardness at room temperature in the delivery condition: 420 - 480 HBW

The Brinell hardness shall be determined in accordance with DIN EN ISO 6506. The hardness shall be measured roughly 1 mm (0.039 in.) below the surface of the plate.

Number of tests

Unless otherwise agreed upon in the order, the Brinell hardness shall be determined from each heat.

Properties typical of 15 mm (0.591 in.) plate thickness

Carbon equivalent CET in % [CET = C + (Mn + Mo) / 10 + (Cr + Cu) / 20 + Ni / 40] : 0.35

Carbon equivalent CE in % [CE = C + Mn / 6 + (Cr + Mo + V) / 5 + (Ni + Cu) / 15] : 0.55

Yield strength in MPa (ksi) *) : 1200 (174.0)

Tensile strength in MPa (ksi) *) : 1400 (203.0)

Elongation at fracture A in % 10

Notch-bar impact energy at - 40 °C (- 40 °F) on

Charpy V-longitudinal test piece in J (ft lbf) 30 (22.1)