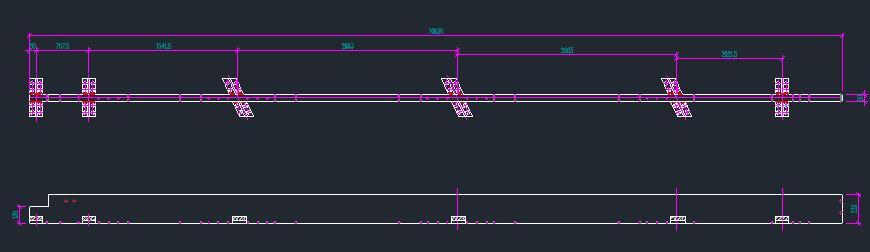

Recently, we have fabricated 100 tons of steel structure parts for our customer. These are kind of long steel strip steel structure. It looks simple steel structure parts, but It is not so easy to fabricate and it is challenging work.

Main difficulties and treatment methods

1. The straightness of the steel strip. We know there must be some distortion after flame cutting for such long steel strip. In addition, the flatness of the steel plate also has a certain deviation.

The drawing requires that the straightness error should not exceed 2mm both in cutting surface direction and original steel plate surface direction, this requirement is very high for such a long steel strip. We know for such long steel strip parts and such thick material, the flatness of 3mm is quite normal.

Regarding cutting deformation, we cannot use large machine tools (such as gantry milling machine or gantry planer, or Floor boring and milling machine) to do machining along the length direction, because the cost is too high and the cost budget is not allowed. We have to use very very traditional method to correct the distortion, which is eighther use heating correction by flame torch or mechanical correction by oil press. In view of the poor command of flame correction, since flame heating correction is not easy to control, so we decide to adopt 300tons oil press. No matter what method is used to correct it, it is not easy to reach 2 mm of straightness

At the beginning, it took two workers 4 hours to correct one part, slowly, with more and more experience, the correction time from 4 hours have been cut done to 2 hours, if A worker's hourly wage is 30 yuan, the labor cost for correction one piece is 60 yuan, which is basically acceptable.

2. The second problem is welding deformation.

Because it is a quite long part, so the thickness of plate is relative very “thin”, so it is easy to cause deformation when do welding on it. Once the deformation is out of tolerance, it is very difficult to correct it and cost is very high. There are three ways to deal with the deformation: First, machining, as mentioned before, it is very expensive. Second way is flame heating, but it is difficult to control. Third way is mechanical correction - hydraulic oil press (in fact, it is no longer realistic because of the wing plates welded on).

Of course, the best way is not to do straightness correction; minas try to control the welding deformation within the acceptable range of tolerance, not out of tolerance. The method is to weld each pair of symmetrical ear-plates at the same time,it is not necessary to do welding by two welders at the same time, after all, the parts are small and the height of the welding is not very large, so it can do by one welder and one layer welding for one era-plate after another layer welding for another ear-plate, purpose is not to let one era-plate overheating (or should say one side of long steel strip), overheating can cause greater deformation.

According to the actual measures after welding by using the symmetrical ear-plates welding, the straightness in the total length direction is not exceeded, and it is still within 2 mm.

3. The most difficult part is how to ensure the accuracy of distances between holes. The drawings require that the distances deviation between any two holes should not exceed 1 mm, for such a large steel structure part, the requirement are very high. Of course, we can do machining and the tolerance is easy to reach, but the same reason we mentioned before that the cost is too high and we cannot bear. So we have to find another way to control the distance tolerance during assembly and welding. How to reach? Drawing line and marking and drilling by radial drilling machine or magnetic drill after welding? It is not good way, if there are only few holes, that are feasible, for such many holes and long distance between holes, it is not possible.

How to ensure the distance between the holes on the longitudinally adjacent ear-plate? and the holes distance on the symmetrical ear plate at the same location? 2 methods;

3.1 The holes distances in two directions need positioning and assurance, one are the holes on the longitudinally adjacent ear-plate (we define it as longitudinally adjacent ear-plate); another are holes on the symmetrical ear plate at the same location (we define it as symmetrical ear plate).

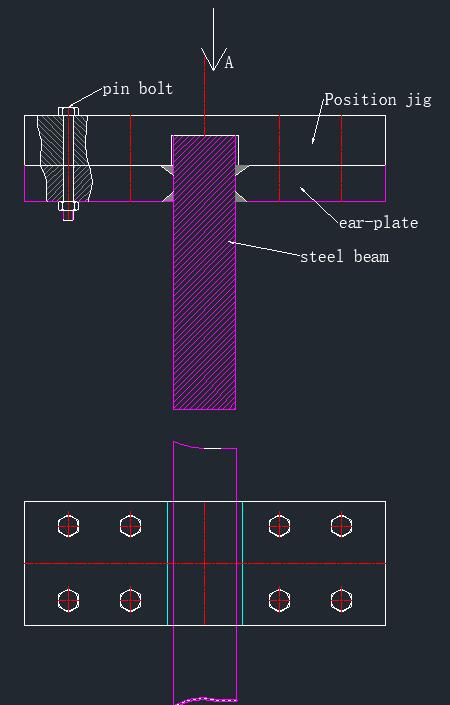

The holes and countersunk holes on the ear plate must be machined and finished firstly, and also the surface which contact with girder must be machined for position purpose.

Firstly, position the symmetrical ear plate and do welding, see the illustrative diagram, it is simple. Fixing the 2 ear-plates on positioning jig by using pin bolt then put the positioning jig on the steel beam, and then welds the two era-plates on the steel beam. So the holes position can be decided.

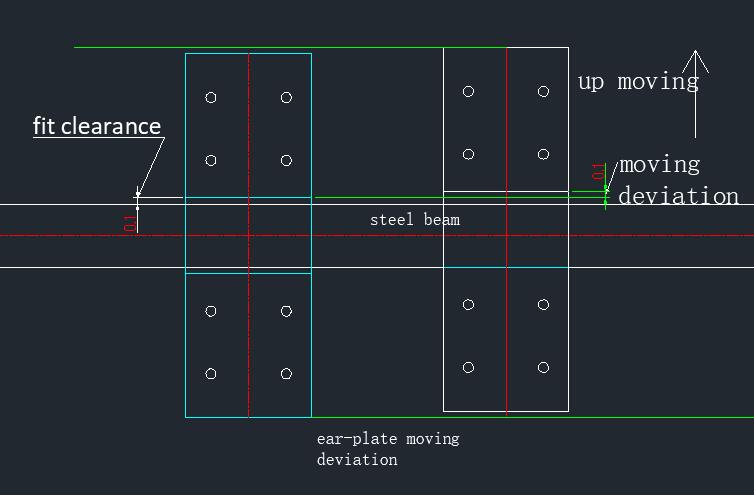

This positioning by the position jig has 2 error points, one is displacement error due to fit clearance between the position jig and steel beam; another one is angle error also due to the fit clearance, both the 2 error will cause the holes position deviation, see the illustration below.

Set up the fit clearance as 0.2mm(we think 0.2mm is reasonable, after all the contact surface of the steel beam is raw material surface, it is not smooth and flat), so the position jig can up-down move, the minimum moving distance is 0.1mm, means the position of holes on the ear-plate has location deviation. But 0.1mm is very small for steel structure parts, and they do not have cumulative errors, so it can be ignored.

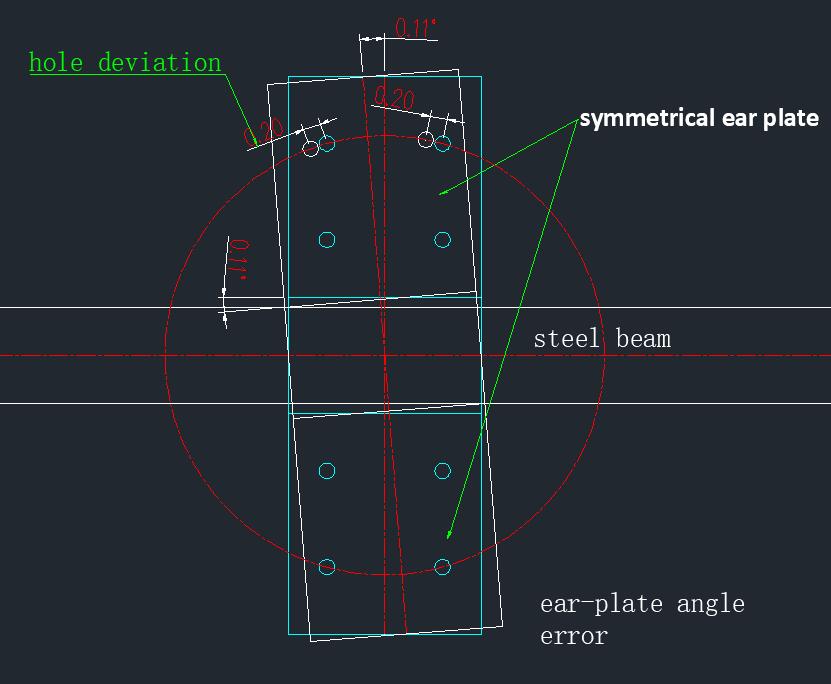

Let’s analysis angle error. See illustration below. The clearance is 0.2mm, the position jig can rotate by 0.11º(calculated), means the outermost row holes can move by 0.2mm distance, single 0.2mm is not much, it is still acceptable, but we have to consider the it can generate cumulative errors, because there 6 pairs ear-plate along the steel beam, assuming that all the 6 pairs ear-plate rotate in same direction, the cumulative deviation is 6*0.2= 1.2mm, means the distance deviation between first row holes to last row holes is 1.2mm, it is a little out of tolerance(requirement is below 1mm), but we also should consider that there is no such thing as coincidence that all 6 pairs ear-plate rotate in the same direction.

3.2 After the analysis of these two errors, it will not have a great impact on the hole spacing error, we can ignore these two errors. Then the key to ensure holes distance accuracy is how to ensure the distance between two adjacent two ears. It is not easy to ensure the distance accuracy within 1 mm between two longitudinally adjacent ea-plates for steel structure or welding structure parts, why? Because, (1) the distance between two ear-plates is quite long, (2) It has cumulative deviation. Only ensure the distance tolerance between the two longitudinally adjacent ea-plates within 0.2mm, then the total holes distance deviation between first row holes and last row holes can be controlled with 1 mm. It is impossible by marking and drilling, of cause it is easy by machining, but it needs big machining tools, it is expensive.

We have to use another position plate, it need a few position plate, because there are a few deferent distance between ear-plates. Laser cutting position plate is good enough; laser cutting can reach linear precision by 0.2mm. Method is same with previous positioning jig, once first ear-plate is fixed on the beam then we can use pin bolt connect the ear-plate and position plate at both ends, so the second ear-plates are positioned, then we weld the second ear-plate on the beam, one by one finishing all the 6 pairs ear-plates.

It looks a simple steel structure works, but it involves machining works, but it cannot be machined for cost reason, it makes it difficult and challenge. In any case, finally we finish the works satisfactorily by using the traditional way.