Compared with the traditional milling machine, CNC machining need higher requirements for the tool, not only the good rigidity and high precision, but also the high stability and high durability, and chip removal performance also should be good and efficient. At the same time installation and adjustment should be convenient and easy to do, thus to meet the requirement of High Efficiency NC machine bed.

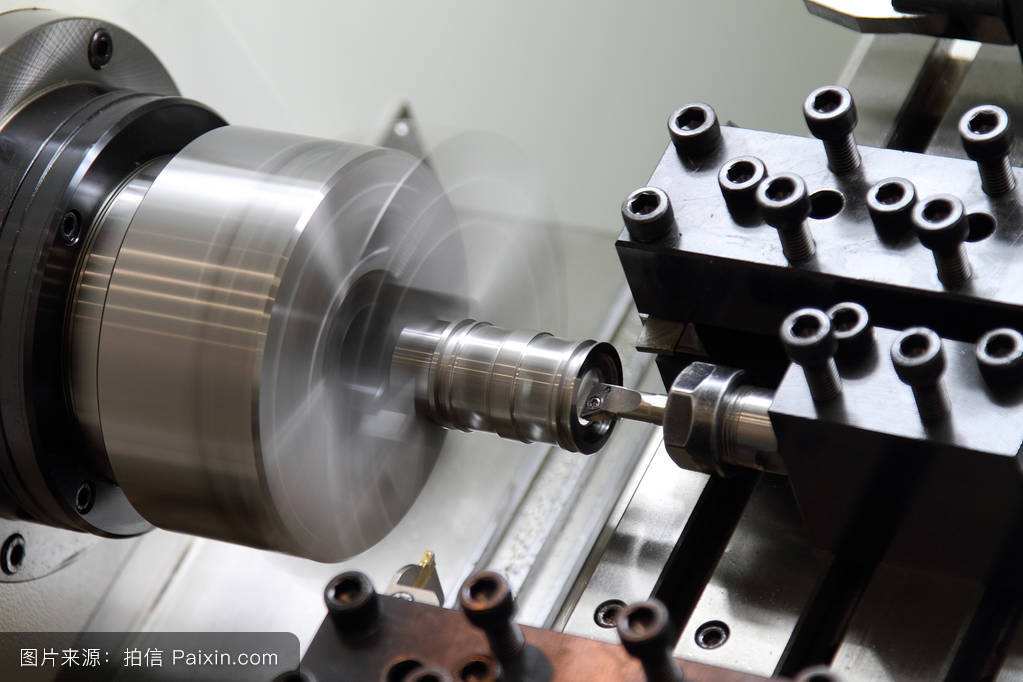

The selected cutters should be suitable for high speed cutting (such as high-speed steel, ultra fine grained cemented carbide indexable insert and use). Turning tool commonly used tool and choosing the numerical control turning generally pointed tool, circular lathe tool and the molding tool class three.

To Choose CNC milling fixture has two major requirements: 1. the fixture must have sufficient accuracy and stiffness; 2. positioning reference fixture should be reliable. To select a good fixture, we should consider the following points: 1. Try to use adjustable fixture and other common fixture, avoid using special fixture, to shorten the preparation time of production. For the mass production, we should consider use of special fixture, and strive to simple structure.

Loading and unloading workpiece should be convenient and efficient, in order to reduce downtime of the machine tool. The fixture selected on the machine tool must be accurate and reliable, to ensure that the workpiece in the correct position.

CNC lathe basically has two kinds: one is used for disc type or short shaft parts, the workpiece fixture in the band adjustable chuck jaws (three claw, four claw), by chuck drive rotation; another kind is used for shaft parts, workpiece (毛胚) is mounted on the spindle on the top and the tailstock.

Workpiece fixture on NC milling machine, typically installed in the table, the form can be varied based on the processed workpiece. Such as: Universal bench vice, NC indexing table etc..

Method of mounting workpice of CNC machine tool, CNC milling the same, with ordinary machine tool, a reasonable choice of positioning and clamping is the base scheme, pay an attention to the following 2 points: the unification datum to the design and programming calculation, this is a simple and accurate numerical calculation when programming. Try to reduce clamping times as much as possible, try to processing all machined surface in one position .

In addition, the tool of choice, strict measurement of tool size should be carried out before use in order to obtain accurate data, and these data will be input data system by the operator, through procedure calls to finish machining process, thus produce the qualified workpiece.