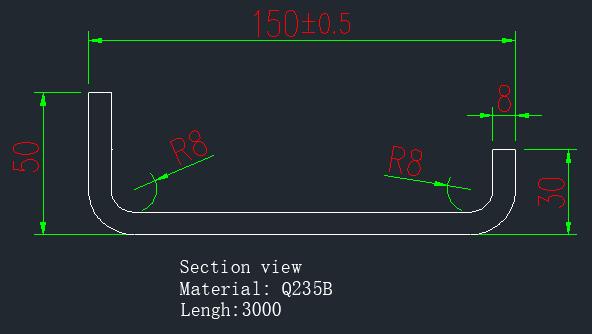

This is a kind of bending part; see below drawing, which I am going to fabricate Shanghai Chian. The length is 3000mm by the way.

Looks simple part, but the width tolerance is±0.5, it is quite tight and it is not easy to reach by simple bending, specially for such long and thick plate bending part.

There are three way to fabricate this part I think. Let’s discuss and analyze the three methods in terms of precision and cost.

1. Normal bending.

I am not really sure if bending can reach the tolerance of ±0.5, because it is quite long part and relatively thick plate. Maybe bending can reach the tolerance by using precision CNC bending machine, let’s analyze the production efficiency and cost. (1) In order to ensure all the quality are uniform and production is efficient, the material should be cut by laser cutting, it is more expensive, but it can ensure the material size precision, further it ensure bending dimension precise. (2) Another extra cost is that the short side is too short to be bent(width is shorter than V –groove width), so this side has to be purposely left longer than original drawing, after bending the extra length should cut by laser cut. It sounds simple, but actually it really not cheap work, because it is very slow, every time only one part can be cut and every part has to be poisoned, it is really a waste for such expensive laser cutting machine, means it is expensive.

2. Using cold draw pipe.

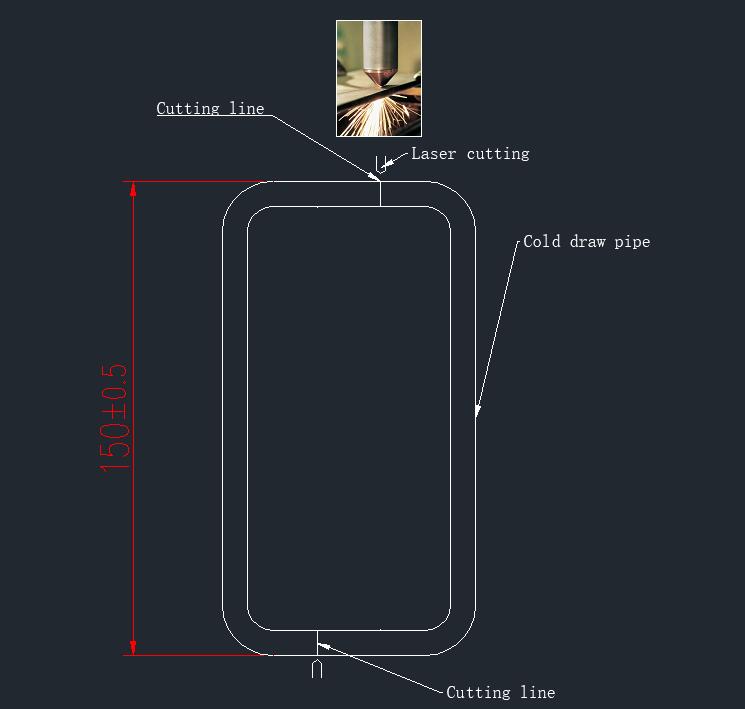

The second way is to use cold draw pipe to fabricate this part, by this way the dimension tolerance must be precision. See the diagram.

Firstly make cold draw pipe with outside dimension 150*80, see diagram above. Dimension of cold draw pipe is very precise, the tolerance of outside dimension can reach as high as ±0.2mm, it is much higher than drawing requirement. After finish the cold draw pipe, and then it has to be cut in half by laser cutting machine. But it is expensive way I think, because firstly material (seamless pipe, no welded pipe can be used) is already more expensive, and it has extra cost--laser cutting too, it is expensive, reason is same with the situation in the first way mentioned above, it is even more expensive than first, because it has tow line laser cutting.

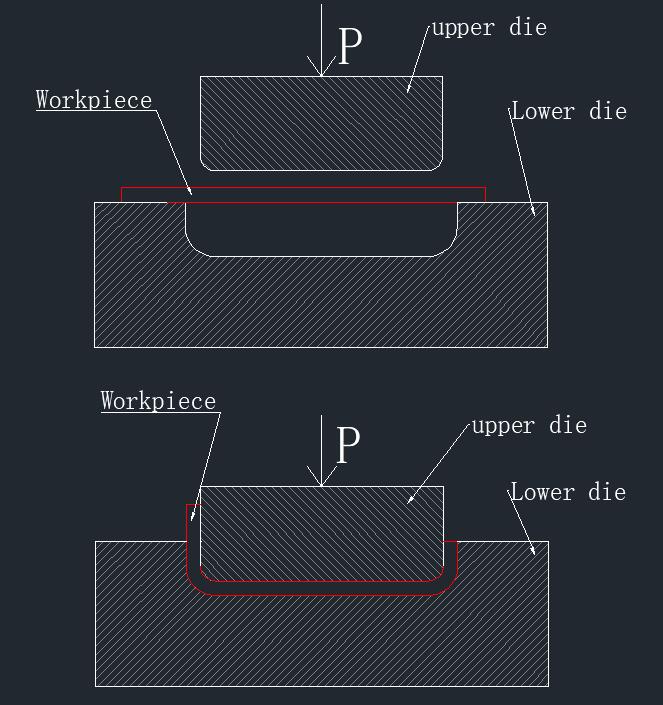

3. Press or called stamping fabrication

We can use upper mould and lower mold to press, see diagram below.

By this way, the precision should be good, and also production is high efficient, means it is cheap, but advantage is that one pair of press mould have to be made, it is big machining parts, it cost some money, it production has big quantity, the cost is ok.

Material prepared should be by laser cutting to ensure bending parts dimension precision.

Let’s make summary for the three ways. See the diagram.

|

|

Raw material |

Preparation |

Mould |

Main production |

Finish cutting |

| First way |

Steel plate |

laser cutting |

No |

2 press |

laser cutting |

| Second way |

Steel plate |

laser cutting |

yes |

1 press |

no |

| Third way |

|

seamless pipe |

yes |

cold draw |

laser cutting |

First way material preparation is ok, no bending dies cost, main production step is not expensive, only two press, but finish cutting is more expensive because it is slow, it is kind of waste for laser cutting machine. Another disadvantage is that the quality is not stable, there is some scrap rate, and it is really costing.

Second way, material preparation is seamless pipe; it is more expensive than steel plate, but considering material preparation no laser cutting, so the price should be same with steel plate plus laser cutting. The main production step- cold drawing is more expensive than other first way (first way is just one bending), most expensive step is finish cutting.

Third way, the material preparation is normal, and the precision of finished part should be good, production is high efficiency (only one press). There is a mould cost, but it is not much considering massive production. And the quality is stable.

In general, third way is much cheaper and quality is acceptable. Second way is most expensive way. What do you think?