I often purchase small and middles size welding components or should I say light structure, I am always frustrated by the small mistakes or defects (listed below), I have to emphasize again and again, some of suppliers just do not pay attention on it, they think it is not very important and it will not affect the function of machine and quality (it do really affect the quality, some time seriously). So I make a summary for this mistakes and defect which often happen and ignore when in welding, fabrication.

1. Conforming the requirements of product drawings,

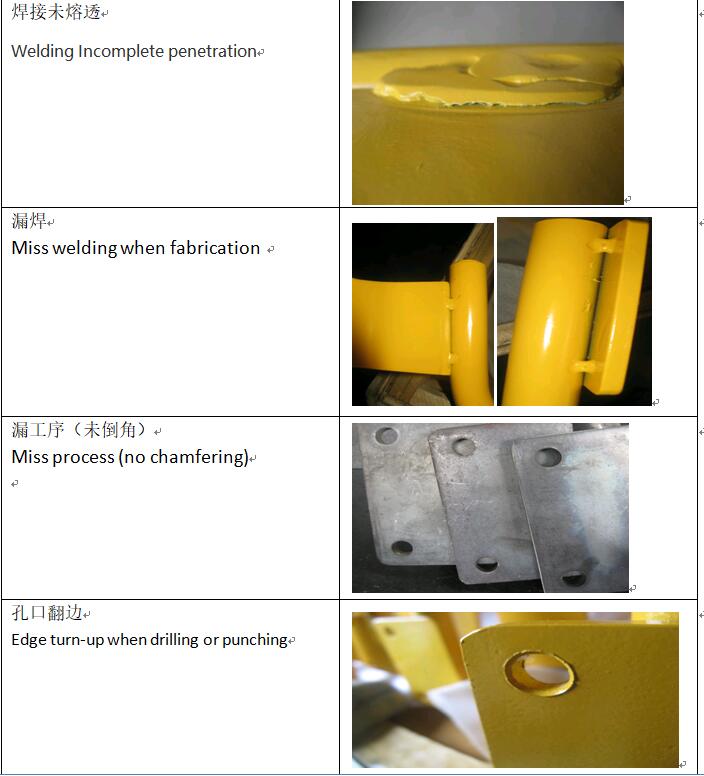

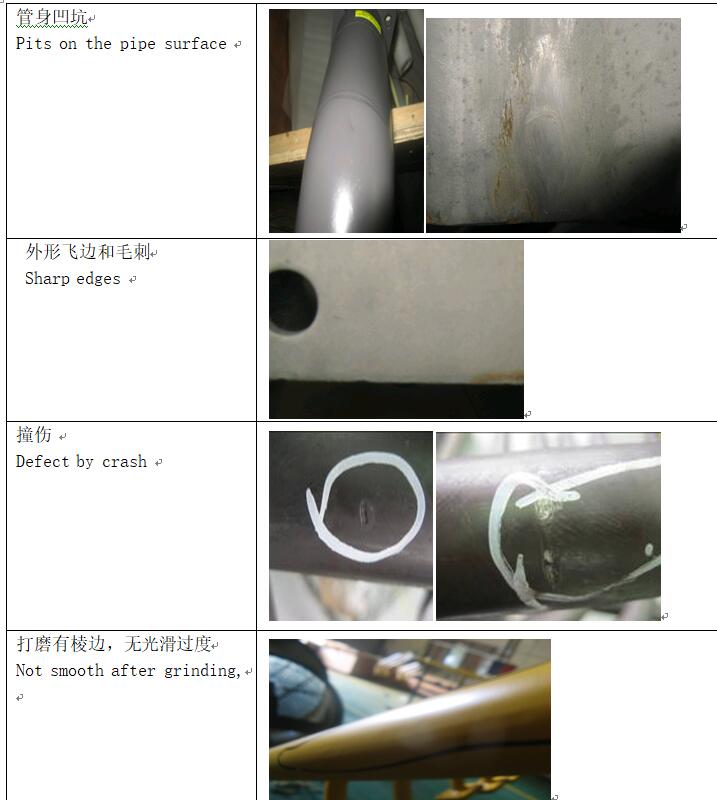

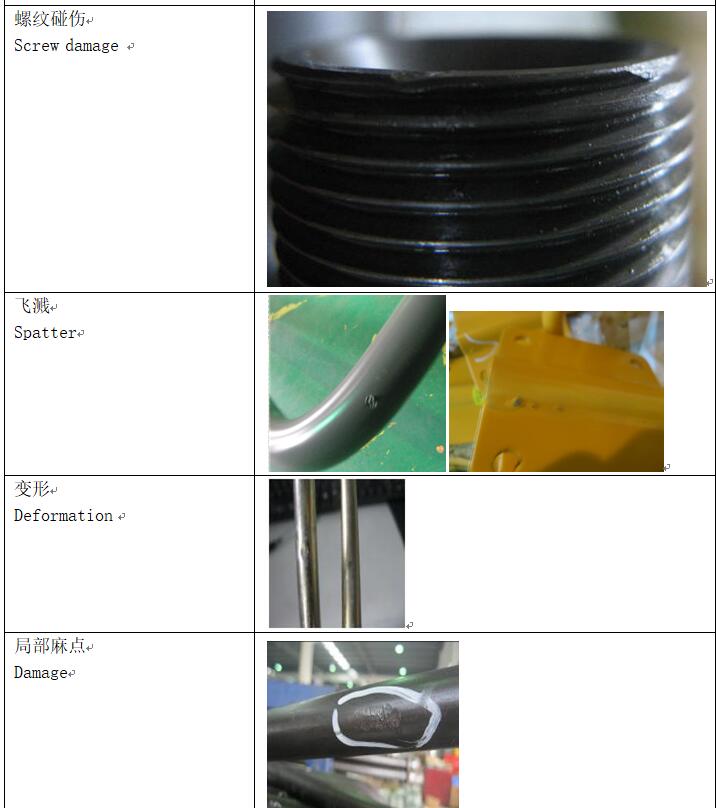

2. Welding acceptance standard conforms to STD180-0001, the listed items below, included but not limited, is unacceptable in terms of welding quality.

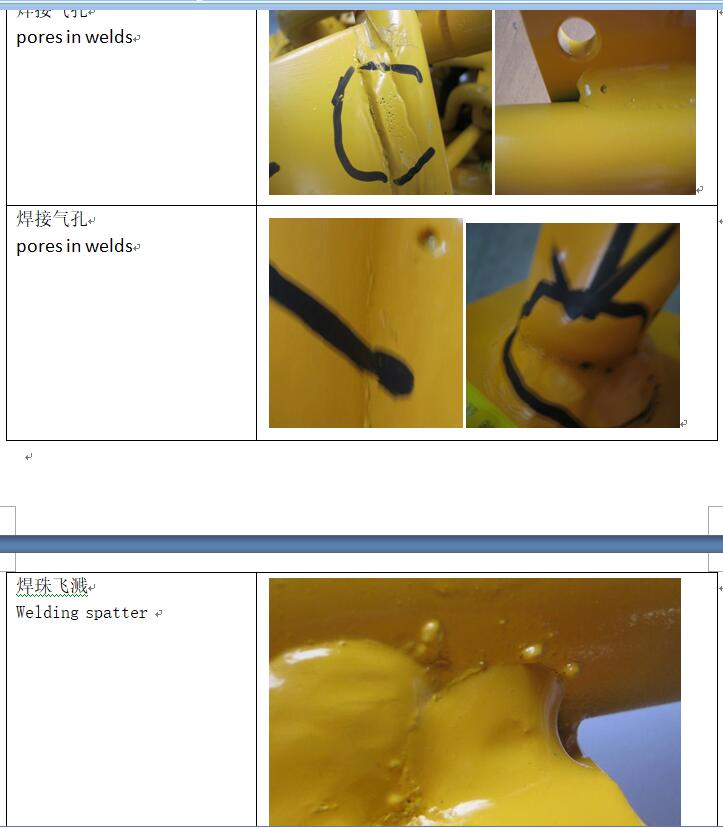

A: Incomplete penetration, B: Miss welding, Burn-through, pores in welds, C: No grinding the weld beading on the welding seam. D: Size of welding spatter is more than 0.5mm. E: edge turn-up, F: Over depth of indentation, and it more than half of base plate thickness tolerance. H: Crash on the material surface and the depth of pit is more than half of base plate thickness tolerance, edge turn-up, and sharp edge. J: The pits are concentrated in the formation of local pock, K: Defect of appearance, L: Miss a process (no chamfering).

Acceptable criterion :

1)Surface of pipe should be smooth, should no visible crack, scar, folds, scars, rolling, separation, slag, splash, flanging, and pitting , these defects must be grinded and cleaned. The transition zone should be smooth and the grinding depth should not exceed half of the thickness tolerance in this area.

2)No spatter is allowed in the pipe orifice and no splash is allowed on the pipe. The spatters in the dead angle, if quantity is less than 3 and diameter of spatter is below 0.5mm, it is acceptable.

3)Part with pit and slight scratch or indentation, and it no sharp edge, flanging and in addition it also meet the criterion below, then it is allowed to accept:

Pipe class;

A. if pipe wall thickness ≤2, then the smallest depth of grinding 0.1mm; B. if pipe wall thickness ≤3, then the smallest depth of grinding 0.25mm; C. if pipe wall thickness ≤4.5, then the smallest depth of grinding 0.35mm;

Other steel structure components class;

Outside diameter ≤30, then the smallest depth of grinding 0.2mm; Outside diameter ≤40, then the smallest depth of grinding 0.3mm; Hand touch without sense of concave-convex。

4)Grinding must be smooth.