Abstract: due to the characteristics of welding itself, some welding defects, such as welding deformation and residual stress, are hard to avoid. In order to improve the quality of welded structural parts, welders have done a lot of work on welding methods, welding materials, and corrections after welding. It has been proved by a lot of practice that the vibration-aging method can effectively reduce or eliminate the welding stress of welded structural parts, reduce welding deformation, ensure product quality, improve production efficiency and reduce manufacturing cost. In view of these advantages of VSR, this paper describes the principle of vibration-aging application in detail, Combining with the practical application of VSR in ultra-high strength steel welded structures, it is proved that VSR is feasible and effective to deal with the problems in welded structures

Welding technology has been widely used in various fields of modern industrial manufacturing. As the welding temperature is very high, the welding temperature drops sharply after the welding, and there is a sharp change of temperature field around the welding,therefore, there are some residual welding stress and welding deformation around the weld, Vibration aging is a aging technology that USES vibration aging equipment to conduct sub-resonance vibration of structural parts and eliminate residual stress, Vibration aging process has the advantages of less energy consumption, high efficiency and environment friendly. There are also quite a number of articles and some technical data at home and abroad which have proved that VSR is a very practical technology. The following is a discussion on the application of technology, VSR technology and its development prospects.

1. Application of Technology

1.1 The vibration-aging technology is to use a controlled vibration energy to

process the metal structural parts to eliminate the residual stress of welded

structural parts, The internal stress of workpiece can be balanced by vibration

aging, and the stress level of workpiece can be in a stable state. The

technology was introduced into China in the 1970s and has been developed for

several decades and has been applied to a certain extent, however, there are

still many problems with the traditional vibration aging, that is, there are

technical problems with the sub-resonance technology that have not been solved

for decades and cannot be incorporated into the formal process by most Chinese

steel structure manufacturers. Therefore, it has not been widely accepted and

applied on a large scale

1.2 After vibration aging treatment of structural parts, it lacks the ability

to measure residual stress. On the one hand, due to the high price of residual

stress measurement equipment, it requires professional personnel to operate and

increases the cost, for practical application units such as factories, it is

not necessary to purchase residual stress measurement equipment; On the other

hand, the measured residual stress does not have relevant authoritative

technical indicators to assess, and does not have a convincing force. So these

two aspects limit the application of vibration-time technology.

1.3 Human factors have great

influence on the aging technology of vibration. The operator selects the

technical parameters of the vibration aging equipment according to the level

and experience; different welded structural parts have different resonant peaks

for complicated welded parts. It is difficult to find resonant peaks for

structural parts without certain practical experience. However, the general

production unit is short of such technical talents, which results in that the

application level of vibration-aging technology cannot be improved and

popularized.

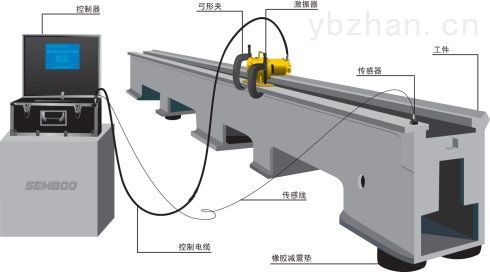

2. The development of vibration-aging equipment

As the vibration aging technology has the unique advantages of energy saving, consumption reduction and high efficiency compared with other aging technologies, the new technology of vibration aging has gradually been recognized and accepted by people. With the development of science and technology in recent years, some new intelligent vibration aging technology and equipment have emerged, which solves the technical problems existing in the old vibration aging vibrator, The new equipment is more about eliminating the old equipment's over-reliance on people, reducing the influence of human factors, so the aging vibrator is gradually replacing the thermal aging technology.

3. Establishment of vibrating aging process

3.1 Basic process parameters of vibration aging

3.1.1 For the selection of vibration frequency: Each steel structure component has several

resonant frequencies of different vibration modes, which are related to the

shape, weight, material and structural rigidity of the structural parts, and is

the inherent characteristic of the structural parts. The vibration aging

equipment can detect the resonant frequency of the structural parts, including

the peak frequency, by the frequency sweeper. After finding the resonant peak frequency, the workpiece

should avoid the peak resonant frequency, carry on the resonance in the

sub-resonant region, in the workpiece vibration process, must pay attention to

adjust the vibration frequency at any time until the vibration is completed.

3.1.2 Selection of excitation force: In the aging process of vibration, the

magnitude of excitation force is measured by the stress value of welded

structural parts, as an important parameter of the aging process of vibration,

the selection of excitation force should be determined according to the factors

such as different materials, geometric shapes, sizes and weights of the

vibrated parts.

3.1.3 Selection of vibration time: The vibration time should be determined

according to the structure and weight of the structural parts, the size and

distribution of residual stress. In current production practice, there are

several methods to determine the vibration-aging time:

- According to the vibration peak, amplitude and vibration force change of vibration exciter in the vibration process of welded structural parts.

- According to the weight of the structural parts to determine.

- According to the basic stopping time of plastic deformation during vibration of structural parts.

3.2 Vibration-aging process

The adoption of a new

process must be combined with actual data to show whether its function can meet

the predetermined requirements. For the new process of vibration aging, we

verify through vibration aging test that vibration aging has obvious advantages

for vibration stress elimination.

3.3 Vibration-aging process

The welding structure of the box body is used as the vibrating workpiece, the

process sequence of the box during vibration aging is as follows.

3.3.1 Selection of mode of vibration of the workpiece: Firstly, the workpiece

is supported horizontally with elastic support, and three-point support is

adopted to balance the workpiece. Then, the exciter is clamped onto the upper

end of small axle hole on the joint surface of the box. The "+" cross

appears when the box body vibrates, so the vibration aging of the box body is

the first order bending and torsional vibration mode.

3.3.2 Selection of vibration frequency: When the box body is vibrating, the

resonance peak appears at 5890 RPM. In order to ensure the box body to run

smoothly in the process of vibration and prevent the real vibration point from

moving to the back edge of the resonance peak, the gear shift during vibration

is added with one gear, and the vibration threshold rate is selected at 5657

RPM.

3.3.3 Selection of excitation force: When the box starts to vibrate, adjust the

eccentric distance of the exciter to the minimum, gradually increase the speed

within the sweep frequency range of the equipment, find the resonant peak by

observing the change of acceleration value, and when the resonant peak is

found, make the maximum acceleration value meet the range requirement by

adjusting the magnitude of the excitation force.

3.3.4 The choice of vibration time: The high frequency band where the resonance

peak occurs during the real vibration. After 30 minutes of vibration, the

process parameters of the t39804-3a box during the real vibration are as

follows: The peak value

after the amplitude frequency curve a-d is higher than the peak value before

the vibration, and the peak point after the vibration is shifted to the left

before the vibration, which fully conforms to the regulations of the mechanical

industry standard of the People's Republic of China /T 5926-91. This time the

vibration is qualified.

Conclusion: Residual stress will be generated in the

workpiece due to the deformation caused by thermal expansion, cold contraction

and mechanical force during welding of metal welded structural parts. As a result, a stress field is formed, which

makes the workpiece in an unstable state,as long as some external force is

applied to it artificially, the residual stress in the workpiece can be

released. After vibration-aging treatment, the internal stress of the workpiece

developed towards equilibrium, and the metal internal structure of the

workpiece did not change, we have proved this effectively through our

experiments. The application of the high efficiency, energy saving, pollution

free and environmental protection vibration-aging stress elimination technology

will significantly improve product quality and reliability. With technical

progress and continuous improvement, the aging vibration instrument will be

applied more and more widely in China steel structure manufacturers.