The manufacturing method of welded H steel has been widely used in many countries and regions. In welding forming, no matter what welding method is used, the key problem is how to control welding deformation. From the past experience, in addition to CO2 welding with concentrated heat and small welding deformation, the rigid fixing method of equal height support rod is also used. Through many times practice and exploration by our company, we use double hook “two claw puller " anti-deformation device through rigid fixation to prevent welding deformation, it has better effect and more convenient operation.

The welding deformation of H steel beam includes flexural deformation, side bending, distortion, tilt of wing plate (angular deformation) and so on. Most of the flexural deformation is caused by the uneven placement of h-type steel girders during welding. During welding, H type steel girder is placed on a special movable jig frame, so that the Angle weld is in a horizontal position, and flexural deformation can be avoided.

Side bending caused by improper welding sequence, grid voltage fluctuation (caused by welding current when large or small), the dimension of cutting parts and assembly out of tolerance, and improper placement (unequal) of H–beam; When the upper and lower flanges are connected with the process support rod, the thermal free expansion of the metal is obstructed by the process support rod and the upper and lower flanges at the beginning, which makes the metal plastic deformation under the action of the fixed rod tension in the high temperature region. But in the process of welding, it is an inhomogeneous heating process for the whole structure, the weld is not completed at the same time, the first part of the weld is affected by the transverse shrinkage of the later weld, which limits the transverse shrinkage of the later weld. Therefore, with the support rod connecting and fixing method, the distortion and the tilt of the wing cannot be well controlled.

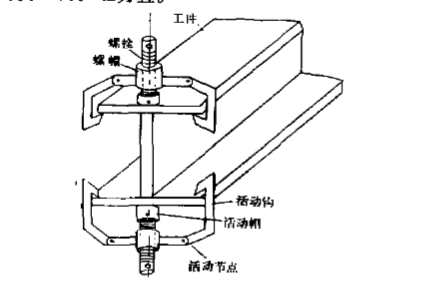

The H-beam produced by our factory is 12 meters long, 400-600 mm wide, 16-22 mm thick, 1140-1400 mm high, 12-14 mm thick, and made of Q235B steel plate. The parts dimension of cutting should be strictly controlled within the allowed range. Considering the deformation of steel caused during transportation and loading and unloading, correction is necessary after cutting and unloading and before assembly. Before welding, the method of connecting upper and lower flanges with support rods was changed to the method of " two claw puller " with double hooks to prevent deformation (Drawing 1). Practice has proved that this method is better. This tool is simple and practical, does not waste bar material, and can reduce the trouble of removing welds for welding bars. The double-hook " two claw puller " anti-deformation device is made of leftover materials with plate thickness of 25-30mm, width of 45-60mm, bolt diameter of 40mm and length of 400mm. Before welding H-beam, a double hook " two claw puller " device was placed on the upper and lower flange at the same distance to prevent deformation. The device was fixed on the upper and lower flange plates by fastening bolts to make the force moderate. The spacing is generally 300-400mm.

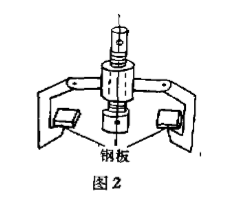

If a steel plate with an area of 100 * 100 mm and a thickness of 25-30 is welded on the movable hook of the double hook " two claw puller " type deformation prevention device, the effect is better (Fig. 2). The purpose of doing this is to increase the contact area of the active hook and wing plate. The H-beam installed with the “two claw puller” is placed on a movable frame so that no matter which weld is welded, no inclination of the upper or lower flange due to lateral contraction of the fillet weld will occur. This is mainly due to the double hook " two claw puller " type deformation prevention device tightly sleeved on both sides of the wing edge, so that the positive and negative forces to achieve a balanced result. During welding, the thermal expansion and cooling shrinkage of the flange metal change under the condition of basic equilibrium. Therefore, not only the inclination of the wing plate is prevented, but also the deflection, side bending and distortion are well solved.

Practice has proved that it is simple and effective to control welding deformation of H-beam by using double hook "pulling horse" type deformation prevention device,All the H-shaped steel beams produced meet the design requirements without any other corrective measures due to excessive deformation.