Cost control is the key to the survival and development of sheet metal processing enterprises. How to manage and control the production cost of sheet metal processing is the permanent goal of all sheet metal processing enterprises. In particular, China's sheet metal manufacturers.

For this big topic, I have followed the practice and experience of management in the sheet metal processing plant for many years, combination with the experience of communicating with some peers in some sheet metal processing enterprises, I put forward some ideas of my own on major cost control points, discuss with each colleague, hope can obtain a bit resonance, achieve the goal that throws a brick to attract jade, drive sheet metal processing enterprise to increase profit, control cost, enhance enterprise competitive power.

Cost control condition

Under normal circumstances, sheet metal processing enterprises are processed according to the requirements of customers, completely processed in OEM mode. The main features are as follows: various types and appearances, and a large proportion of small batch diversity; Different shapes; Quantity sometimes more sometimes less; The size and appearance some require strict and some require loose; Prices range from high to low; Delivery times some vary from long to short.

We discuss the cost control of sheet metal processing manufacturers, limited to the following conditions: small and medium-sized sheet metal processing enterprises, the number of personnel less than 400, the annual output value of less than 200 million yuan; The processing technology is mainly punching, cutting, folding, pliers, welding, assembling, machining, plating and spraying. The product variety and quantity are more or less, and the orders of many customers are produced in parallel. The materials used are mainly cold plate, aluminum plate and stainless steel.

Under the above conditions, the number of Chinese sheet metal processing enterprises is already large (take nanpi county, hebei province as an example, there are over 3980 sheet metal stamping enterprises in the whole county), The annual output value is about 12 billion yuan in total, among which most enterprises are small in scale, the average output value of single enterprises is about 3 million yuan, among which there are 8 enterprises with output value of 100 million yuan, 28 enterprises with output value of 50 million yuan and 81 enterprises with output value of 20 million yuan.

Product cost analysis

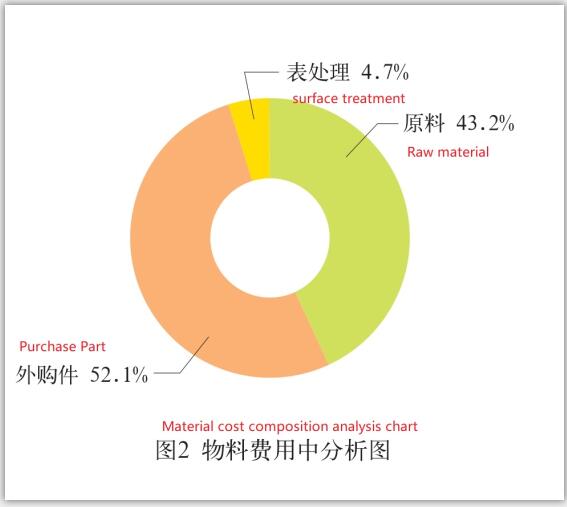

Take my previous sheet metal processing factory as an example, we have summarized the production cost in the past two years according to the four major items of material cost, personnel cost, operation cost and financial cost, as shown in figure 1

Cost control point

1. Material cost

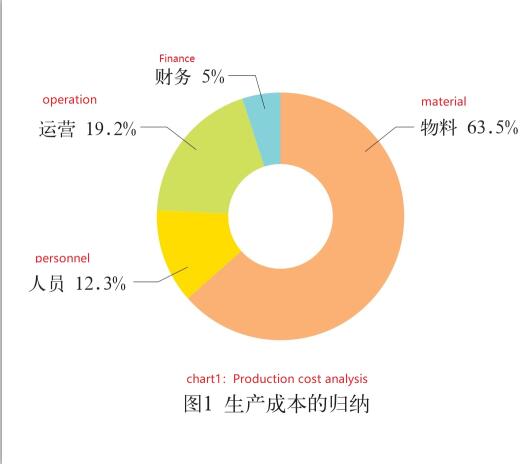

The control of materials cost in sheet metal processing enterprises is the top priority of cost control. The key points of materials cost control are as follows:

1.1 The raw materials

The control of material cost should be based on the principle of price priority, and the key points of control are the quantity of purchase, payment method, depth of cooperation and negotiation, which need stakeholders to check

The use of quantity control mainly through the following measures to solve: the control of materials, control the occurrence of excess materials taking; reasonable punching and cutting nesting (material utilization); The emphasis is to control materials in the production process of the enterprise; Use professional nesting software and assign someone to be responsible for nesting; Improve the secondary utilization rate of waste materials; A clear reward system; The emphasis is on the rationality of the engineer's shop drawing design to reduce waste from the design.

1.2 Purchased components.

The key to control the cost of purchased parts is to control the purchase price. The specific methods and standards are as follows: control the purchase quantity, delivery time, payment conditions, etc., and the price has no absolute bottom line; Key personnel/professional personnel/community of interests/power personnel/responsible personnel control price points; Every material price should be discussed, from 0.01 yuan to thousands of yuan a material price should be discussed; for a single material, monthly, quarterly, semi-annual, annual cycle attention to the amount of procurement, in and out of storage quantity, unit price, payment conditions, etc. Under the conditions of customer satisfaction, continuous development of new suppliers is carried out under the same material.

Participants: technical personnel, purchasing personnel, senior executives, production personnel, etc., full participation, who participates in who benefits, there are clear incentives.

2. Personnel costs

Personnel cost control: Set annual target (take 2014 as an example): per capita output value 860,000 yuan / person; per capita wage 5800 yuan / person / month; bonus target 12 million yuan.

Small accounting units (Amiba operation and management); independent accounting, income distance widened, timely cash; community of interests, 1/3 of the company's shareholders;

Development direction

Standard cabinet (chassis) + customization + Internet is the future development direction of sheet metal processing industry. The functions, specifications, structure, appearance and price of standardized cabinets (chassis) are all universal and open. Make sure that our customers'designers and purchasing managers, especially our executives, are very willing to pay attention to and ensure that our products are attractive. Standard cabinet (chassis) body + standard configuration = conventional requirements (materials, specifications, structure, hardware, installation, installation size, standard accessories); The designer of the customer can directly call the standard cabinet (case) he needs through the Internet, and can select the functional cabinet (case) he needs from the standard cabinet (case) function library. And you can change the size, color, installation position and standard accessories by operation. You can also carry out standardized structural design by yourself. For example, the interior of the cabinet (case) has its own special requirements, the opening requirements on the standard mounting plate, the size of beams, supporting plate and opening requirements, etc. The notes can be retrieved from the original standard parts library to be modified or their own design drawings can be uploaded, and the original customized parts can be returned

Standardization, networking, visualization. After the customer designer has designed the standard cabinet (case) and the parts that need to be customized, they can negotiate the bill of lading online. After the production department receives the order, the classification is completed according to the standard preparation requirements and special types of parts in the order. The standard parts enter the company's standardized process and the customized parts enter the company's customized workshop. The conventional processing shall be collected to the assembly and delivery department according to the time and quantity, and the standard customized cabinets (boxes) shall be put into the assembly line production. The customer can monitor the production progress and process in the whole process, directly deliver the goods to the designated delivery place, and monitor the whole process visually. Truly achieve quality stability, price advantages and large quantities of streamlined production.

Take the standard cold plate cabinet of 800mm, 800mm, 2000mm as an example, the production cost can be controlled at around 1300 yuan, and the price is around 1800 yuan. The quantity of orders can be varied from a single machine to several hundred units, and the production cycle is within one week, and the cost is reduced a lot.