In general, we use the amount of steel in welded structure as a major index to measure the advanced industry and advanced welding technology in a country. At present, the average 45% of the steel in the world will become the products through welding. The steel for welding structure in Germany, the United States, the United Kingdom, Japan and other countries account for more than 60% of the country's steel output. With the rapid development of China's industrial modernization, many heavy structures, such as power station boilers, pressure vessels, ships, construction engineering, metallurgical equipment and heavy machinery, tend to be large, large-scale and efficient, the amount of steel used in the welding structure has risen greatly, according to incomplete statistics. In 2010, the steel consumption of the welded structure of our country exceeded 45% of the consumption of China's steel, exceeding the average level of the world.

At present, welding steel structures instead of casting is widely used in the manufacturing of large machine tools and valves in the large state-owned manufacturing industry, and all kinds of advanced welding technologies are widely used in the steel frame, railway, highway bridge and urban traffic construction etc. steel structure.

In general, except for a

few technologies and technologies, China's welding technology is not far from

the world level. It belongs to the second group after Germany, America, Britain

and Japan.

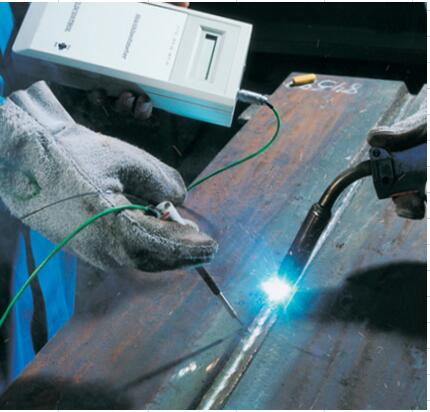

Welding is to connect metal materials together, mainly used in heavy machinery,

power equipment, petrochemical industry, transportation, construction

engineering, aerospace and other industries, electronic devices, household

appliances, medical equipment, communication engineering, etc. There are also

some welding services.

Welding disciplines include materials science, mechanics, heat treatment,

metallurgy, automatic control, electronics, inspection and so on.

The welding of our country started from 156 aspects of Soviet aid, and was also

taught by Soviet elder brother. Until the Soviet Union tore up the aid agreement in 1960, there

was no real welding technology and equipment in China, only a Soviet Union

welding technology and equipment users. It was not until 1972 that our country

independently established several welding equipment manufactory. At present,

the domestic large-scale general welding equipment manufacturers include

Shanghai Dongsheng, Shanghai Hugong, Shanghai GM, Kelda, Shandong Great

Olympics, Yuci Jingwei and so on.

After the reform and

opening up, the technical backbone of these large welding equipment factories

have been poached, and many small and medium sized welding equipment

factories have been set up in Jiangsu and Zhejiang provinces, but they mainly

produce simple welding operators, roller frame, welding positioner and turnover

machine and so on, which are low in the degree of automation. At present, small and

medium sized general welding equipment manufacturing enterprises include Wuxi

Han God, Shanghai wentley, Shanghai Hua Wei, Shanghai zheng special, Nantong

rich force, Chengdu Huayuan, Chengdu bear Valley, Chengdu welding research and

technology, Chongqing transportation, Tangshan treasure, Guangzhou beacon fire,

Shenzhen rayling strength, Shenzhen rayling appliance, Dongshan, etc. The development of these private enterprises

will ensure and promote the development of welding manufacturing and welding

structures in China.

After 80s, the Western technology

blockade has been relaxed, and some non military welding equipment can be

imported. Some of the central enterprises of our country have introduced a

large number of welding equipment under the technical transformation projects. These

devices have a high level of automation (real eye opener, such as the universal

use of mechanical control, PLC control and CNC Systems), and high equipment

accuracy. The introduction of these equipment has made great progress in

automation welding technology in China.

In 1996, China began to import a large number of welding robots. By 2001, there were 1 040 welding robots, of which 49% were arc welding robots and 47% were spot welding robots. (at present, more than 2 million robots are used in the world, of which welding robots account for more than 45% of all robots, and the proportion of robot robots in China is about 50%. In 2014, there were 200 thousand robots in China, of which 100 thousand were welding robots - this data is the data of the Chinese robot industry alliance. There is an exaggeration of suspicion)

At present, most of the welding equipment in active service of large state-owned manufacturing enterprises in our country adopted automatic control system, intelligent control system and network control system and so on, and the welding robot is widely used as operation unit, and the welding center, welding production line and integrated manufacturing system are formed.

At present, in China's large-scale manufacturing industry, welding has developed from simple component connection or blank manufacturing to one of the precision processing methods in manufacturing industry, especially in large steel structure manufacturing, such as steel frame of machine tools, pressure vessel, steel frame of other machines, railway bridges etc. It has realized the welding process method and process scheme without the direct participation of human, as well as the structure and configuration of welding machinery equipment and welding system, and realized the automation of welding inspection and assembly inspection (i.e., the automatic welding process without the direct participation of human).

Of course, small

businesses, private enterprises rely on manual welding or widespread

phenomenon.

At present, China's welding technology has developed from a single processing

technology to comprehensive engineering technology, including materials, welding

structural design, welding process methods, welding equipment and process

equipment, welding materials, welding preheating treatment, cutting down

material, groove processing, welding technology and related standards, welding

production, welding.