Abstract:Under the background of accelerating pace of modernization in China, the manufacturing industry ushered in a new development opportunity. Mechanical manufacturing and machining technology has made great progress, providing reliable technical support for the development of our society and economy. In order to meet the actual demand of machinery manufacturing in the market, the relevant personnel must effectively master the processing technology of mechanical manufacturing and machining tools equipment, and improve the application value of the mechanical manufacturing process.

Key words: Mechanical manufacturing; mechanical equipment; machining technology

1. Introduction

In order to meet the actual demand of the domestic market for the machinery manufacturing industry in the 4.0 era of the industry, we must strengthen the research and development of mechanical manufacturing technology and machining technology, and improve the technological level of the mechanical manufacturing field as much as possible. Mechanical manufacturing technology and machining technology are widely used in the current market, especially in the fields of electronics and manufacturing, it has very high application value. In this regard, the practitioners of mechanical manufacturing industry must strengthen the understanding of the machining technology and mechanical equipment, and only in this way can we ensure the rapid development of our machinery manufacturing industry.

2. Mechanical manufacturing technology

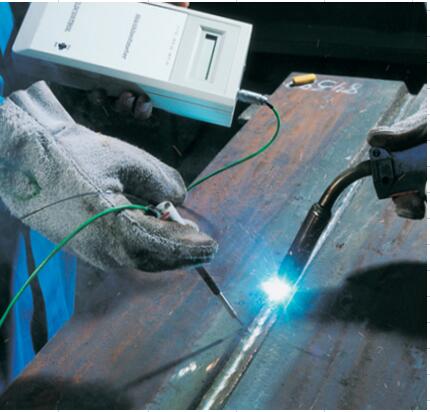

2.1 Gas shielded welding process

Gas shielded arc welding uses arc as heat source, gas as protective medium in welding process, and the corresponding welding work is accomplished by arc action. In the process of gas protection welding, the protective gas is continuously sent to the arc and covering arc, gas can effective separate the arc, molten pool from air, which can effectively avoid the influence of other gases on the welding quality during the welding process. As far as gas shielded welding gas is used, carbon dioxide is widely used because of its stable carbon dioxide, low cost and high quality of welding.

2.2 Resistance welding process

The principle and process of resistance welding technology, two objects to be welded shall be connected to the positive and negative electrodes of the power supply, and use the "electric length effect" on the contact surface produced by electric to melt the contact surface of the welding material, and then exert certain pressure on the welded materials to weld it together. Resistance welding technology has high quality and high welding efficiency; it does not require high level of personnel operation technology. At the same time, in the welding process, it does not need more time and it has less pollution to the environment, so it has been widely used in today's manufacturing field, especially in sheet metal manufacturing field. However, resistance welding also has some shortcomings. Resistance welding process has a high cost, such as high requirements for equipment, and the maintenance cost of the equipment is large, and the quality inspection of the weld is difficult to carry out.

2.3 Submerged arc welding process

Submerged arc welding is an arc welding method under the flux layer. It has the advantages of stable welding quality, high welding productivity, no arc light and little smoke and so on, which makes it the main welding method in the production of important steel structures such as pressure vessel, pipe section manufacture, box beam column and so on. In recent years, although many new welding methods with high efficiency and high quality have appeared successively, the application of submerged arc welding is still unaffected. From the point of view of the proportion of the weight of deposited metal in various fusion welding methods, submerged arc welding accounts for about 10%, and has not changed much over the years.

2.4 Stud welding process

In the welding process, through the connection of the stud to the plate (or the tube), the contact surface is melted by the arc, and then the pressure is applied to the contact surface to achieve the welding of the components, which is the stud welding process. The stud welding technology can be divided into two kinds of welding modes, which are energy storage and arc pulling. The former is less deep and is more applied to the welding of thin plate than the latter, such as sheet metal fabrication, home appliance industry, office and bank equipment, and the latter is more applied in the field of heavy industry,such as heavy steel structure, mining equipment manufacturing etc. The soldering process of stud is used in single side welding. It does not need to punch and break holes in the welding object, and it belongs to nondestructive welding, it is widely used in the field of modern machinery manufacturing.

2.5 Friction welding technology

Friction welding is a method of welding with the heat produced by the reciprocal movement and friction of the end of the workpiece, which makes the end up to the thermoplastic state and then quickly forged. Friction stir welding (FSW) technology has been widely used in the manufacturing of vehicles and aircraft etc. sheet metal fabrication, and the technology has been mature, the process technology is very high, and the application range is very wide. The application of the technology in the manufacturing field can further reduce the consumption of materials and the wider welding range. Especially in the process of welding of aluminum alloy components, it can effective treat welding with of 800mm thick, and the requirement of temperature is low in the process of welding. It will not change the original material structure of the component, the welding quality is very high, and it can effectively reduce the cost of resources consumed in the welding process, and the economic benefit is more remarkable.